Teaching wire cutting programming to beginners, what are the programming methods?

Wire cutting programming is a highly technical task that requires the operator to have deep mechanical knowledge and program programming skills. In modern manufacturing, the importance of wire cutting programming is becoming increasingly prominent because it directly affects the accuracy and production efficiency of products. The following Zhikai CNC will introduce you in detail the basic concepts, steps and techniques of wire cutting programming, as well as the ways and methods to learn wire cutting programming.

1. Basic concepts of wire cutting programming

Wire cutting programming refers to the process of completing the precision cutting of workpieces by writing CNC programs on CNC wire cutting machines according to design drawings and processing requirements, controlling the motion trajectory and cutting speed of the wire cutting machines. This process involves knowledge of multi-axis motion control, molybdenum wire path planning, and processing parameter settings.

2. Wire cutting programming steps

1. Understand the design drawings: The operator needs to understand the design drawings in detail, including the size, shape, cutting path and other information of the workpiece.

2. Select cutting process: According to the workpiece material and requirements, select the appropriate cutting process, including discharge parameters, cutting speed, electrode shape, etc.

3. Write CNC program: The operator uses dedicated CNC programming software to write CNC program according to the design drawings and the selected cutting process. The program includes instructions such as cutting path, speed control, and stop point.

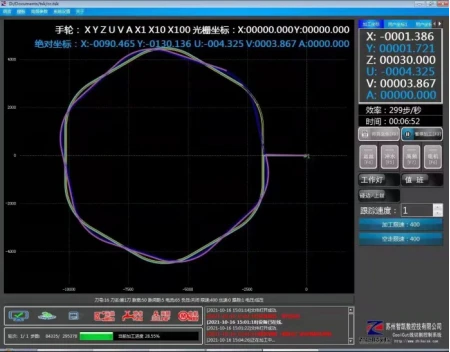

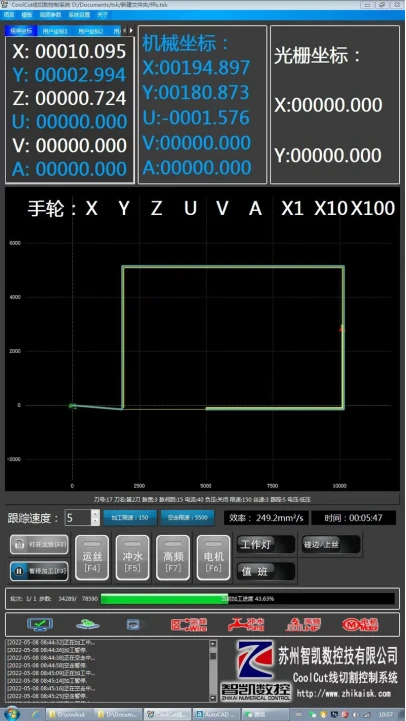

4. Program debugging: After writing the program, it needs to be debugged in a simulation environment or on an actual machine tool to ensure the correctness and stability of the program.

5. Processing monitoring: During the actual processing, the operator needs to monitor the cutting process to ensure the wear of the tool, processing quality, etc.

3. Wire cutting programming skills

1. Accurate measurement: Before programming, the workpiece needs to be accurately measured to ensure the accuracy of the program.

2. Reasonable path planning: The planning of cutting path directly affects the processing efficiency and cutting quality. Reasonable path planning can reduce cutting time and improve production efficiency.

3. Optimize processing parameters: According to the hardness, thickness and other characteristics of the material, adjust the discharge parameters and cutting speed to obtain the best processing effect.

4. Prevent electrode wear: Reasonably set the stop point to avoid the electrode staying in the same position for a long time and reduce electrode wear.

5. Pay attention to the cutting process monitoring: During the processing, monitor the cutting status at any time, find problems in time and make adjustments.

4. Ways and methods to learn wire cutting programming

1. Professional training courses: There are many training institutions that provide training courses on wire cutting programming. These courses usually include theoretical knowledge and practical operations to help students master wire cutting programming skills.

2. Online tutorials and videos: There are a large number of wire cutting programming tutorials and video resources on the Internet. Students can acquire knowledge through self-study and master the basic skills of wire cutting programming.

3. Practical operation experience: Practical operation is one of the most effective ways to learn wire cutting programming. You can get practical experience in wire cutting programming through internships, work, etc. Start with an apprenticeship. Instead of learning online, it is better to work first. You can learn by doing and receive an apprentice salary.

4. Reference documents and books: When learning wire cutting programming, you can refer to relevant programming manuals, technical documents and professional books to deepen your understanding and mastery of knowledge.

5. Participate in industry exchanges: Wire cutting equipment is divided into fast wire cutting and medium wire cutting. Medium wire cutting has a relatively high technical content. You can participate in more industry groups and forums to communicate with industry experts and peers to obtain the latest wire cutting processing technology and technical guidance.

in conclusion

Wire cutting programming is a task that requires deep technical skills and practical experience, but through systematic learning and continuous practice, anyone can master this skill. When learning wire cutting programming, it is very important to understand the basic concepts, master the programming steps and techniques, and choose the right learning path and method. Through continuous learning and practice, better results can be achieved in the field of wire cutting and contribute to the development of modern manufacturing. If you are near Jiangsu, you can come to Suzhou Zhikai CNC Wire Cutting Company for on-site exchanges and learning, and learn and understand advanced wire cutting technology.