How to generate machining trajectory steps in wire cutting CAD? Wire cutting machine tool manufacturer [Zhikai CNC]

Wire cutting CAD is a commonly used CNC machining technology used to cut flat materials into desired shapes. Generating machining tracks is one of the key steps of wire cutting CAD. The detailed steps of generating machining tracks will be introduced below.

1. Import CAD file: First, import the CAD file that needs to be wire-cut into the wire-cut CAD software. Usually, the format of the CAD file can be DXF, DWG, etc.

2. Create cutting path: Create a cutting path on the imported CAD file. The cutting path can be a straight line, a curve, or a complex shape, designed according to actual needs.

3. Set cutting parameters: Set cutting parameters according to the properties of the material and cutting requirements. Cutting parameters include cutting speed, cutting depth, cutting angle, etc. Different materials and shapes require different cutting parameters.

4. Generate cutting trajectory: Generate cutting trajectory based on cutting path and cutting parameters. The cutting trajectory is the path that the cutting machine moves on the material, which can be a straight line, an arc, or a complex curve.

5. Optimize cutting trajectory: Optimize the generated cutting trajectory. Optimizing the cutting trajectory can improve cutting efficiency and cutting quality. Common optimization methods include path planning, path smoothing, and path optimization algorithms.

6. Generate processing code: Generate processing code based on the generated cutting trajectory. The processing code is the control instruction of the cutting machine, which is used to control the cutting machine to cut according to the cutting trajectory.

7. Simulate the processing process:

Before generating the processing code, you can simulate the processing process. By simulating the processing process, you can check whether the cutting trajectory is correct to avoid errors.

8. Export the processing code:

Export the generated processing code to the cutting machine. Usually, the format of the processing code can be G code, M code, etc.

9. Processing verification:

Before actual processing, perform processing verification. Through processing verification, you can check whether the cutting trajectory is accurate and whether the cutting parameters are appropriate.

10. Actual processing:

According to the generated processing code, perform actual processing. During the processing, you need to pay attention to safe operation to ensure the safety of the cutting machine and the operator.

The above are the general steps for generating processing trajectories. The specific operation methods and processes may vary depending on different wire cutting CAD software. In actual operation, it is also necessary to adjust and optimize according to specific needs and material characteristics. Through reasonable settings and optimization, the efficiency and quality of wire cutting can be improved, and more accurate cutting results can be achieved.

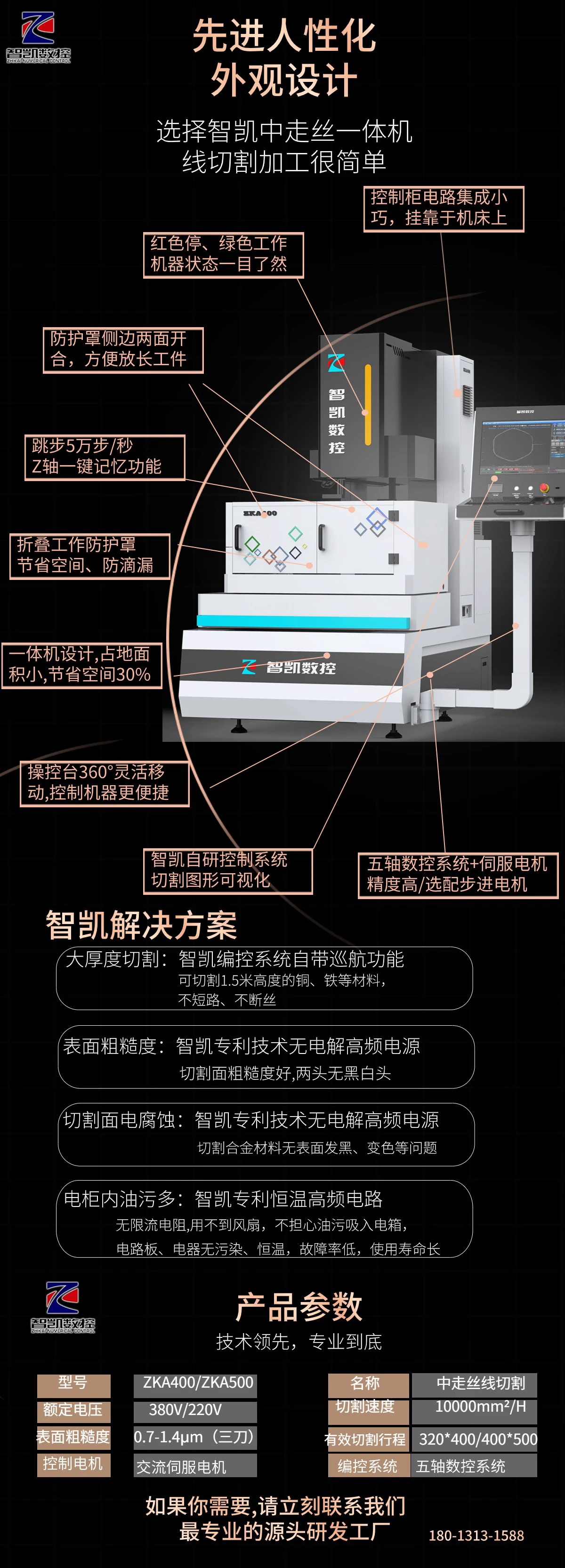

Zhikai CNC adopts the self-developed Coolcut wire cutting control system, which provides advanced functions such as one-key material collection, overtravel prediction, image skipping and slow wire AR table to meet the processing needs of different users. As a leader and innovator of medium-wire wire cutting technology, Suzhou Zhikai CNC Co., Ltd. continues to promote the improvement and development of this technology. We are committed to providing high-precision, high-quality medium-wire wire cutting solutions, and have won the trust and acceptance of a large number of small and medium-sized enterprise users in the market. Welcome to consult Zhikai CNC: 180-1313-1588!