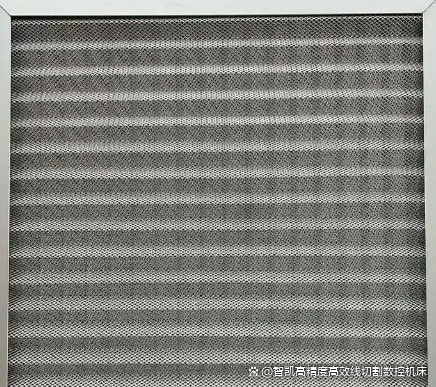

Filter screens: C-type three-axis wire cutting machine tool processing in water treatment equipment

In today's era of increasing environmental awareness, the advancement of water treatment technology is not only related to the efficiency of industrial production, but also directly affects our quality of life. Imagine how to ensure water safety without efficient and accurate filter screens? Today, we will explore the unique role of a key process - C-type three-axis metal wire cutting machine tool processing in filter screen manufacturing.

Case Customer Product Analysis: Breakthrough and Improvement

For companies committed to providing high-quality water treatment solutions, the accuracy and durability of the filter screen are key factors in determining its performance. These filters are usually made of stainless steel or other corrosion-resistant materials and are used to remove suspended particles and impurities from the water. However, with the increasing requirements for water quality, traditional processing methods can no longer meet the needs of modern design, especially in processing complex geometries and microstructures.

After using a C-type three-axis wire cutting machine, the company is able to achieve precise control of the filter mesh aperture, down to ≤±0.003mm or even smaller, while ensuring edge smoothness and consistency of the overall structure. According to actual application data, after using this technology, the service life of the filter is extended by about 35%, while the production cost is reduced by about 20%. This not only significantly improves the market competitiveness of the product, but also brings higher economic benefits to users.

Discussion on processing difficulties

Although the C-type three-axis wire cutting machine provides many conveniences for filter screen manufacturing, it still faces some challenges. For example, for the processing of ultra-thin materials (thickness less than 0.5mm), how to avoid material deformation and heat-affected zone (HAZ) is particularly prominent. In addition, as the design tends to be more complex, such as when multiple functional units need to be integrated in a limited space, higher requirements are placed on machine tool stability and programming flexibility.

Zhikai CNC has solved these problems through continuous technological innovation. We have developed a cooling system optimized for fine processing, which effectively reduces thermal damage. At the same time, we provide comprehensive software support, so that even complex 3D models can be accurately converted into physical objects. All these efforts are to make every detail perfect.

Summary: Trust Zhikai and create a clean future together

"The truth is in the details, and the ingenuity is in the precision." This sentence perfectly summarizes the important role of C-type three-axis metal wire cutting machine tools in the manufacture of filter screens. In addition to serving the filter screen manufacturing in the water treatment field, Zhikai CNC is also widely used in many fields such as automobile manufacturing and aerospace. With continuous R&D investment and a complete after-sales service system, we are committed to providing customers with comprehensive technical support and solutions.

Whether you are looking for ways to improve product quality or want to reduce production costs, Zhikai CNC is your trustworthy choice. Because we know that behind every technological innovation is to create a cleaner and better world. Let us work together to explore unlimited possibilities!

With strong technical strength and strict quality management, Zhikai's medium-speed wire cutting machine tools have become the first choice for many manufacturing companies, such as lighting equipment: LED street lamp head radiator, textile machinery: precision parts of spinning machines, plastic product molds: fine processing of injection mold cooling channels, etc. The advanced CNC system and precision technology ensure the smooth operation of the machine tools with low errors; the full after-sales service allows customers in Xunyang City, Zhenping County, Langao County, Pingli County, Hanyin County, Ziyang County, Shiquan County, Ningshan County, Baihe County, and Hanbin District to experience meticulous support. Zhikai is willing to work with you to create efficient production and a better future. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machines, we will soon launch related popular science articles such as high-angle wire cutting for high-angle machines, 1-meter linear rail wire cutting EDM, 1-meter high-rigidity wire cutting machine, micro stepper EDM wire cutting, large micro-glossy surface spark wire cutting, F-type high-workpiece wire cutting machine, DK7735 herringbone wire cutting machine, C-type servo wire cutting EDM, 2-meter high-end EDM wire cutting, etc. Everyone is welcome to visit and obtain relevant solutions.