The behind-the-scenes hero of the fine structure of the ink cartridge: the secrets of the large-scale new medium-speed wire cutting machine tool processing

In the printing machinery industry, the fine structure of the ink cartridge is a key factor in determining the printing quality. Are you curious about how these precision parts are made? The large new medium wire cutting machine plays an indispensable role in this. Today, let us uncover the mystery of the processing of the fine structure of the ink cartridge and see how Zhikai CNC helps the printing machinery industry improve quality.

1. Ink cartridge fine structure and processing difficulties

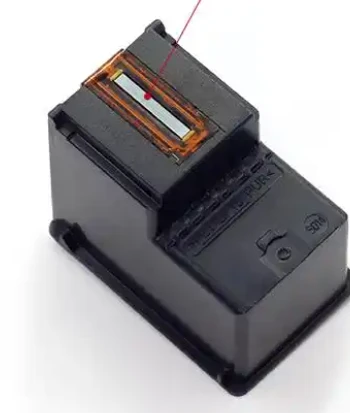

Ink cartridge nozzle

The ink cartridge nozzle is the core component of the ink cartridge, and its precision directly affects the printing effect. The difficulty in processing lies in the small nozzle aperture, complex shape, and extremely high concentricity requirements. Zhikai CNC's large-scale new medium-speed wire cutting machine, with its high precision and high stability, perfectly solves this challenge.

Cartridge housing

The difficulty in processing the ink cartridge shell lies in its complex curved surface structure and dimensional accuracy. The fine processing capability of the new medium-speed wire cutting machine ensures the tightness and aesthetics of the shell and improves the overall performance of the cartridge.

2. Case Customer Product Analysis

Taking a printing machinery company as an example, the fine structure of its ink cartridges is processed by Zhikai CNC's large-scale new medium-wire machine tools. Data shows that the printing accuracy of ink cartridge nozzles processed by Zhikai CNC equipment has increased by 20% and the failure rate has decreased by 30%. The processing quality of the cartridge housing has also been significantly improved, further enhancing the market competitiveness of the product.

3. Zhikai CNC, industry-leading cutting solutions

Focus on R&D, technology leads innovation

Zhikai CNC always adheres to technological innovation to provide customers with efficient and stable medium-speed wire cutting solutions. In the printing machinery industry, Zhikai CNC has successfully helped many companies improve product quality and won wide recognition.

Perfect after-sales service to ensure worry-free use

Zhikai CNC is well aware of the importance of after-sales service and provides customers with a full range of technical support. From equipment installation and commissioning to operation training and after-sales maintenance, Zhikai CNC is always by the customer's side to ensure the stable operation of the equipment.

Summarize:

"Ingenuity creates precision, and innovation leads the future." In the printing machinery industry, Zhikai CNC's large-scale new medium-speed wire cutting machine provides strong support for the fine structural processing of ink cartridges. In addition, Zhikai CNC is also widely used in the cutting of other parts, such as gears, cams, molds, etc. Choosing Zhikai CNC means choosing quality and trust. Let us work together to create a brilliant future for the printing machinery industry!

Zhikai CNC is a medium-speed wire cutting machine manufacturer and professional slow-speed wire cutting system solution provider with 20 years of R&D and manufacturing experience. Its products are widely used in food processing machinery: complex shape cutting of juicer blades, wind power generation: wind turbine main shaft bearing seat, ship navigation equipment: positioning device in ship automatic driving system, wind power generation: metal parts of generator stators and rotors, jewelry: realization and optimization of complex design of precious metal jewelry. The projects are spread across Xinhe County, Wushi County, Wensu County, Keping County, Aksu City, Shaya County, Awati County, Baicheng County, Kuqa City and other cities. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machines, we will soon launch small and ultra-large wire cutting machines, DK7735 three-axis machine tool wire cutting, 7740c machine tool wire cutting, DK7740 AC servo spark wire cutting, T-type two-axis wire cutting machine, 800c wire cutting machine equipment, C-type 63 machine tool wire cutting, 630 large-angle wire cutting equipment, Pin-shaped spark wire cutting and other related popular science articles. Everyone is welcome to visit and obtain relevant solutions.