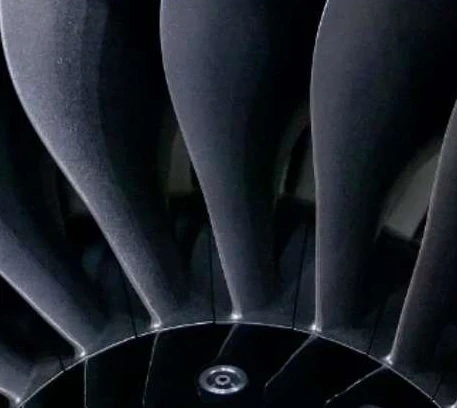

Detail of a fiber separation device: Large-scale wire EDM in textile machinery

In the textile machinery industry, fiber separation equipment is one of the core equipment in the production process, and its performance directly affects the fiber sorting efficiency and quality. The detailed structures of fiber separation equipment, such as sorting screen plates, guide blades, transmission shafts, etc., often need to be completed by high-precision and high-stability processing equipment. The processing accuracy of these detailed structures directly determines the operating efficiency and life of the equipment. This article will deeply explore the difficulties of these detailed structures in large-scale machining of EDM wire cutting machines, and analyze the unique advantages of Zhikai CNC in this field in combination with actual cases.

1. Difficulties in processing the detailed structure of fiber separation equipment

1. Sorting screen

The sorting screen plate is a key component in the fiber separation equipment, responsible for accurately sorting fibers of different lengths. The difficulty in its processing lies in:

High precision requirements: The aperture and hole spacing of the sieve plate need to be controlled within ≤±0.00 3 mm to ensure the accuracy of sorting.

Complex hole patterns: Screen plates usually have hole patterns of various shapes, such as round, square or special-shaped holes, which require high-precision EDM wire cutting equipment for processing.

2. Guide vanes

The guide blade is the core component of the fiber separation equipment, responsible for guiding the movement direction of the fiber. The difficulty of its processing lies in:

Thin-walled structure: Guide vanes are usually thin-walled structures, which are prone to deformation during processing, affecting accuracy.

Complex curved surface: The curved surface of the blade is complex and needs to be processed by multi-axis wire-cut EDM equipment.

3. Drive shaft

The transmission shaft is a power transmission component in the fiber separation equipment. The difficulty in its processing lies in:

High-hardness material: The transmission shaft is usually made of high-strength alloy steel, which is prone to tool wear during processing and affects efficiency.

High surface finish requirements: The drive shaft needs to undergo high-precision surface treatment to ensure its wear resistance and service life.

2. Product Analysis of Case Customers

The fiber separation equipment produced by a textile machinery company uses Zhikai CNC's large-scale machining EDM wire cutting machine tools for its detailed structures such as sorting screen plates, guide blades, and transmission shafts. Through actual production data, we can see:

Processing accuracy: The aperture accuracy of the sorting screen plate reaches ≤±0.00 3 mm, far exceeding the industry standard, ensuring the accuracy of fiber sorting.

Production efficiency: The processing time of guide blades has been shortened by 20%, which greatly improves production efficiency.

Product life: The surface finish of the drive shaft has been significantly improved, and the service life has been extended by 25%.

3. Advantages of Zhikai CNC

1. Focus on R&D and Lead in Technology

Zhikai CNC has always regarded technological innovation as its core competitiveness. Its large-scale machining EDM wire cutting machines adopt advanced CNC systems and intelligent processing technologies, which can meet the high-precision processing needs of complex parts. For example, the equipment is equipped with a high-precision grating ruler and an intelligent temperature control system to ensure stability and consistency during the processing.

2. Perfect after-sales service, trustworthy

Zhikai CNC not only provides high-quality processing equipment, but also provides customers with a full range of after-sales services, including equipment installation and commissioning, operation training, regular maintenance, etc. In addition, Zhikai has also established a rapid response mechanism to ensure that customers can get timely resolutions when they encounter problems.

3. Other parts cutting recommendations

In addition to the detailed structure of the fiber separation equipment, Zhikai CNC's large-scale machining EDM wire cutting machine tools are also widely used in the processing of other parts in textile machinery, such as spinning spindles, loom guides, molds, etc. Its high-precision and high-efficiency processing capabilities have been widely recognized in the industry.

IV. Conclusion

In the textile machinery industry, the detailed structural processing of fiber separation equipment is a process that requires extremely high precision and stability. The application of large-scale machining EDM wire cutting machine tools not only improves the processing accuracy and efficiency, but also significantly extends the product life. With its strong R&D capabilities and perfect after-sales service, Zhikai CNC has become a leader in this field. As a golden saying goes: "Precision determines quality, and service determines the future." Zhikai CNC will continue to be committed to providing customers with high-precision and high-efficiency processing solutions to promote the high-quality development of the textile machinery industry.

Through the analysis of this article, we can see that Zhikai CNC's advantages in the field of large-scale machining EDM wire cutting machine tools are not only reflected in technology research and development, but also in the deep understanding of customer needs and comprehensive services. Whether it is the detailed structure of fiber separation equipment or the processing of other complex parts, Zhikai CNC can provide reliable solutions.

When traditional wire cutting encounters efficiency bottlenecks, Zhikai's third-generation intelligent knife repair technology is saving 15% of molybdenum wire loss for 3,576 customers. We have already answered your processing pain points with modular design: the self-developed constant temperature primary color processing power supply system can handle complex materials, and the rapid response ensures 7×24h stable operation. You can get the "White Paper on Optimization of Parameters for Medium Wire Cutting" for free by consulting now. Zhikai's team of engineers is in place to customize a combination of cost reduction and efficiency improvement for you within three minutes. "Welcome friends from Shaya County, Wensu County, Kuqa City, Awati County, Wushi County, Xinhe County, Aksu City, Keping County, Baicheng County and other places to consult.