Revealing the key components of beverage filling machines, food processing machinery cannot do without six-axis wire cutting machine tools

In the food processing machinery industry, a high-performance beverage filling machine is the key to improving production capacity and ensuring product quality. But did you know that the key components of these beverage filling machines cannot be separated from the fine processing of large six-axis wire-cut machine tools? Today, let us discuss the processing difficulties of these parts and how Zhikai CNC can help the industry break through bottlenecks.

1. Key components and processing difficulties of beverage filling machines

Filling valve

The filling valve is the heart of the beverage filling machine, and its precision and stability directly affect the filling quality of the beverage. The difficulty in processing the filling valve lies in the complex flow path inside the valve body, which requires extremely high precision. The large six-axis wire-cut machine tool can easily cope with this challenge with its high precision and high stability.

Seals

Seals play a vital role in beverage filling machines. Once a problem occurs, it may lead to beverage leakage, contamination and other problems. The difficulty in processing seals lies in the special material and complex shape. The six-axis wire cutting machine can achieve high-precision and high-efficiency cutting to ensure the quality of seals.

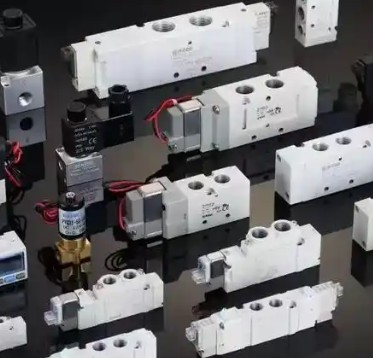

Pneumatic components

Pneumatic components are the key part of beverage filling machine operation, and the difficulty of processing them lies in dimensional accuracy and surface quality. Large six-axis wire-cut machine tools can improve surface quality and reduce the failure rate of pneumatic components while ensuring dimensional accuracy.

2. Case Customer Product Analysis

Taking a food processing machinery company as an example, the key components of its beverage filling machine are processed by Zhikai CNC's large six-axis medium-speed wire cutting machine tools, and the product performance has been significantly improved. Data shows that the filling accuracy of filling valves processed by Zhikai CNC machine tools has been improved by 15% and the failure rate has been reduced by 20%. The processing quality of seals and pneumatic components has also been well received by customers.

3. Zhikai CNC, the industry-leading choice

Focus on R&D, innovation leads the future

Zhikai CNC always adheres to technological innovation as the core, continuously optimizes product performance, and provides customers with efficient and stable cutting solutions. In the food processing machinery industry, Zhikai CNC has successfully provided high-quality services to many companies, helping them improve product quality and reduce production costs.

Perfect after-sales service, so you have no worries

Zhikai CNC is well aware of the importance of after-sales service and provides customers with a full range of technical support. From machine tool installation and commissioning to operation training and after-sales maintenance, Zhikai CNC is always by the customer's side to ensure the stable operation of the equipment.

Summarize:

"Details determine success or failure, and quality creates brilliance." In the food processing machinery industry, Zhikai CNC's large six-axis wire-cut machine tool provides a strong guarantee for the processing of key components of beverage filling machines. At the same time, Zhikai CNC is also widely used in the cutting of other parts, such as gears, cams, impellers, etc. Choosing Zhikai CNC means choosing quality and trust. Let us work together to create a better future!

Zhikai has always adhered to the concept of customer first. For 20 years, it has worked silently and developed its own slow wire cutting system and wire cutting machine tools. Through continuous technological innovation and lean manufacturing, it has created high-performance 2.5-meter small wire cutting equipment, DK7732 large-angle spark wire cutting, large-scale large-stroke machine tool wire cutting, large aluminum alloy wire cutting EDM, C-type precision wire cutting machine equipment, super-large integrated wire cutting machine, micro fine wire EDM wire cutting, large high-precision machine tool wire cutting, DK7735 mirror EDM wire cutting. Precision processing, low failure rate and high stability make production more efficient; perfect after-sales system and technical training escort for customers in Wensu County, Kuche City, Keping County, Xinhe County, Wushi County, Aksu City, Awati County, Shaya County, Baicheng County and other places. Choosing Zhikai means choosing the all-round guarantee of trust, quality and service to create a brilliant future together.