Precision parts of optical fiber connectors: Key applications of 800 simple metal wire cutting machine tools in communication equipment manufacturing

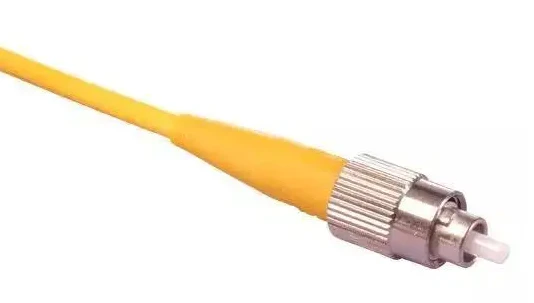

In the field of communication equipment manufacturing, the processing accuracy of precision parts directly determines the performance and reliability of the product. Especially in the 5G era, the precision parts of fiber optic connectors are the core components of signal transmission, and their processing quality directly affects the stability and transmission efficiency of the communication network. How to achieve efficient and high-precision processing of these precision parts? The 800 simple metal wire cutting machine has become a "weapon" in the manufacture of communication equipment. Today, we will use a real case to deeply explore the application of the 800 simple metal wire cutting machine in the manufacture of communication equipment, and how Zhikai CNC creates value for customers through technological innovation and high-quality services.

Case customer: Processing challenges of precision parts for optical fiber connectors

A communications equipment company focuses on the research and development and production of optical fiber communications equipment. Its products are widely used in 5G base stations, data centers, and fiber-to-the-home. As key components for signal transmission, the precision parts of optical fiber connectors have extremely high requirements for processing accuracy and surface quality. The following are the key applications of the 800 simple metal wire cutting machine tool in the manufacturing of precision parts of optical fiber connectors:

1. Connector housing

The outer shell of the optical fiber connector is usually made of high-hardness alloy material, and the dimensional accuracy of its inner hole and outer shape directly affects the assembly performance of the connector. The 800 simple metal wire cutting machine can achieve outer shell dimensional accuracy within ≤±0.00 3 mm through high-precision electrode wire movement and stable discharge machining.

2. Ceramic Ferrule

Ceramic ferrules are the core components of optical fiber connectors, and the roundness and dimensional accuracy of their inner holes are extremely high. The 800 simple metal wire cutting machine can achieve micron-level precision processing of the inner holes of ceramic ferrules by optimizing discharge parameters and electrode wire paths, ensuring accurate docking of optical fibers.

3. Metal end face

The metal end face of the optical fiber connector needs to have extremely high flatness and surface finish to ensure low-loss signal transmission. The 800 simple metal wire cutting machine uses high-precision plane cutting technology to achieve end face flatness error control within ≤±0.00 3 mm and surface roughness Ra ≤ 0.7-1.4 μm.

Processing Difficulties and Solutions

In the processing of precision parts of optical fiber connectors, the main processing difficulties faced by the 800 simple metal wire cutting machine tool include:

1. High material hardness

The outer shell and end face of the optical fiber connector are usually made of high-hardness alloy or ceramic materials. Traditional processing methods easily lead to tool wear and processing deformation. The 800 simple metal wire cutting machine can achieve high-precision cutting of high-hardness materials without contacting the material through electric spark discharge machining.

2. Microstructure processing

The precision parts of optical fiber connectors usually contain micro holes and complex geometric shapes, and traditional processing methods are difficult to achieve high-precision molding. The 800 simple metal wire cutting machine can easily cope with the processing needs of micro structures through high-precision programming and multi-axis linkage.

3. High surface quality requirements

The precision parts of optical fiber connectors have extremely high requirements for surface finish and edge quality. Any tiny defects will affect the signal transmission performance. The 800 simple metal wire cutting machine can achieve a surface roughness of Ra ≤ 0.7-1.4 μm by optimizing the discharge parameters and electrode wire tension control, ensuring the high performance of the parts.

Zhikai CNC: Winning customer trust through R&D and service

As a leading manufacturer of 800 simple metal wire cutting machine tools, Zhikai CNC always adheres to technological innovation as the core to provide customers with cost-effective solutions. Our equipment is not only suitable for the processing of precision parts of optical fiber connectors, but also widely used in the manufacture of other communication equipment parts. The following are several major advantages of Zhikai CNC:

1. Strong R&D capabilities

Zhikai CNC has an experienced R&D team that focuses on the innovation of high-precision processing technology. Our 800 simple metal wire cutting machine adopts advanced servo control system and high-precision grating ruler, which can achieve nanometer-level position control accuracy.

2. Perfect after-sales service

We provide customers with full-process services from equipment selection, process optimization to after-sales maintenance. Zhikai CNC's technical team can provide personalized processing solutions and technical support according to the specific needs of customers to ensure that the equipment is always in the best operating condition.

3. Wide range of application cases

In addition to the processing of precision parts of optical fiber connectors, Zhikai CNC's 800 simple metal wire cutting machine has also been successfully used in the following fields:

-Antenna parts: high-precision radiating elements and reflector processing.

-Filter components: processing of complex shaped resonant cavities and couplers.

-Base station structural parts: precision bracket and shell processing.

Summary: Precision makes communication possible, and services connect the future

In the communications equipment manufacturing industry, precision is the guarantee of product performance, and the 800 simple metal wire cutting machine is a key device for achieving high-precision processing. With its strong R&D capabilities and perfect after-sales service, Zhikai CNC provides customers with reliable solutions to help them stand out in the 5G era.

Zhikai's medium-speed wire cutting machine tools have won the trust of customers with their excellent processing accuracy and stable performance. Strict process control and advanced slow wire cutting function system ensure the efficient operation of ZKA400 copper wire medium-speed wire cutting machine, DK7732 multi-axis medium-speed wire cutting machine, T-type integrated machine EDM wire cutting, 2.5 meters aluminum alloy wire cutting machine, 1 meter molybdenum wire machine wire cutting, 400 super large machine wire cutting and other equipment. At the same time, the whole-process considerate after-sales service makes customers in Shaya County, Kuche City, Xinhe County, Wushi County, Keping County, Wensu County, Aksu City, Awati County, Baicheng County and other places worry-free. Choosing Zhikai means choosing a partner who attaches equal importance to quality and strength, and moving towards the brilliant future of intelligent manufacturing together. In the near future, we will successively launch popular science articles on ZKA400 copper wire medium-cut wire machine, DK7732 multi-axis medium-cut wire machine, T-type integrated machine EDM wire cutting, 2.5m aluminum alloy wire cutting machine, 1m molybdenum wire machine wire cutting, 400 super large machine wire cutting, etc. You are welcome to visit and obtain relevant solutions.