Uncovering the secrets of C-type wire EDM equipment in the manufacture of solar panel frames

In the energy sector, technological innovation is the key to driving industrial development. Today, we will take you into the world of C-type wire EDM equipment, explore its application in solar panel frame manufacturing and its processing difficulties, and provide valuable reference for colleagues in the industry.

1. Case Customer Product Analysis

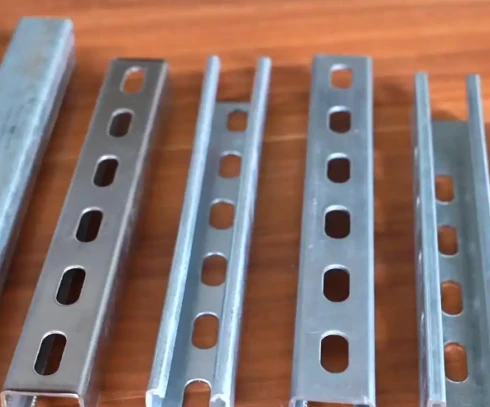

As an important part of solar panels, the manufacturing accuracy of solar panel frames directly affects the stability and service life of solar panels. The following is the application of C-type wire EDM equipment in the manufacturing of solar panel frames:

Frame Accuracy: Solar panel frames require extremely high dimensional and shape accuracy to ensure proper installation and operation of the panels.

Material properties: The electrical and thermal conductivity of common frame materials such as aluminum alloys poses challenges to the cutting process.

2. Processing Difficulties and Solutions

Precision control: C-type wire EDM equipment, with its high precision and high stability, effectively ensures the dimensional accuracy of the frame.

Material cutting: In view of the electrical conductivity and thermal conductivity of materials such as aluminum alloy, the C-type EDM wire cutting equipment adopts special technology to ensure cutting quality and efficiency.

Surface quality: The equipment generates little heat during cutting, which avoids damage to the surface of the material and ensures the beauty and practicality of the frame.

3. Advantages and recommendations of Zhikai CNC

Zhikai CNC has the following advantages in cutting parts in the energy field:

Focus on R&D: Zhikai CNC has always been committed to the innovation of wire EDM technology to provide customers with better quality and more efficient cutting solutions.

Perfect after-sales service: Zhikai CNC provides a full range of technical support and services to ensure that customers' equipment runs worry-free.

Cutting recommendation: For the energy sector, the following parts are recommended to be processed using C-type wire EDM equipment:

a. Precision gears: For precision gears with high precision requirements, C-type wire EDM equipment can provide ideal processing results.

b. Complex shape parts: C-type EDM wire cutting equipment is suitable for processing complex shape parts to improve production efficiency.

Summarize

In the energy field, C-type wire EDM equipment provides strong technical support for the manufacture of solar panel frames. Zhikai CNC, with innovation as its driving force and service as its foundation, provides reliable cutting solutions for colleagues in the industry. "Precise cutting promotes the development of green energy." Choose Zhikai CNC to create a better future!