Unveiling the application of 800 eight-axis cutting machine tool in fine processing of injection mold cooling channels

In the field of precision mold manufacturing, a high-quality product is inseparable from advanced processing equipment. Today, we will take a mold manufacturing company as an example to explore the application of 800 eight-axis cutting machine tools in the fine processing of injection mold cooling channels, as well as the processing difficulties of these parts.

1. Case Customer Product Analysis

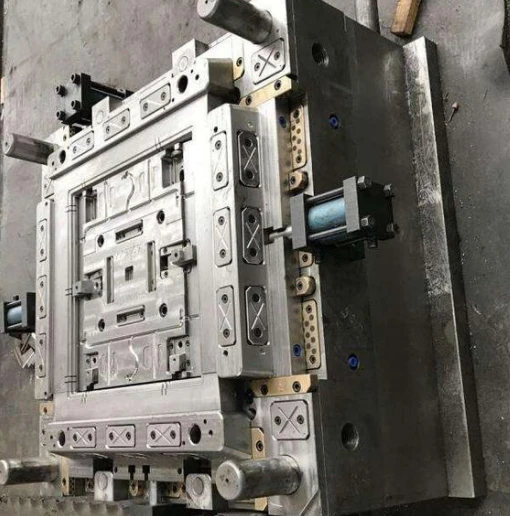

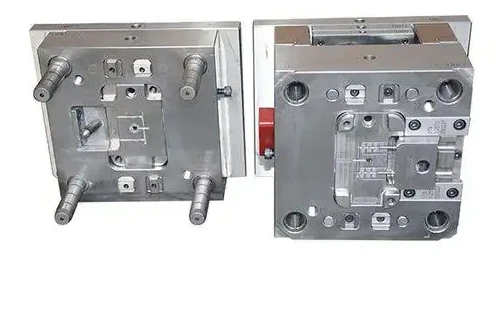

As the core component of plastic product production, the fine processing of the cooling channel of the injection mold directly affects the product quality. In the production process of the mold manufacturing company, the following parts are processed by 800 eight-axis cutting machine equipment:

Cooling channel: The cooling channel is a key part of the injection mold, and its precision requirements are extremely high. Through 800 eight-axis line cutting machine processing, the precise size and shape of the cooling channel can be achieved.

Mold inserts: Mold inserts play an important role in the molding process of plastic products. They have complex shapes and are difficult to process. The 800 eight-axis line cutting machine tool equipment can efficiently complete the processing of mold inserts.

2. Processing Difficulties and Solutions

High precision requirements: The size and shape precision of the cooling channel are extremely high, and a slight deviation may lead to product quality problems. The 800 eight-axis cutting machine tool equipment adopts a high-precision control system to ensure processing accuracy.

Complex shapes: The mold inserts have complex shapes, and traditional processing methods are difficult to meet the requirements. The 800 eight-axis cutting machine tool has powerful graphics processing capabilities and can easily handle complex shape processing.

High material hardness: During the mold manufacturing process, some parts have high material hardness and are difficult to cut. The 800 eight-axis cutting machine tool adopts high-speed cutting technology to effectively improve cutting efficiency.

3. Advantages and recommendations of Zhikai CNC

As a leading domestic CNC equipment supplier, Zhikai CNC has extensive experience in mold manufacturing. The following are Zhikai CNC's advantages and recommendations in the industry:

Focus on R&D: Zhikai CNC always pays attention to the development trend of the industry, continuously develops and innovates, and provides customers with efficient and stable cutting solutions.

Perfect after-sales service: Zhikai CNC provides a full range of after-sales services, including equipment installation, commissioning, training, maintenance, etc., so that you have no worries.

Cutting recommendation: For the mold manufacturing industry, Zhikai CNC recommends that the following parts be processed using 800 eight-axis cutting machine equipment:

a. Mold electrode: The electrode has a complex shape and high precision requirements, and the 800 eight-axis cutting machine tool can easily handle it.

b. Mold slider: The slider processing requirements are high, and the 800 eight-axis cutting machine tool equipment has a fast cutting speed and high precision.

Summary: In the field of mold manufacturing, the 800 eight-axis cutting machine tool equipment provides a strong guarantee for the fine processing of the cooling channel of the injection mold. With its strong R&D strength and perfect service system, Zhikai CNC has become a leader in the industry. Choose Zhikai CNC to make mold manufacturing more accurate and efficient! As the golden sentence says: "If you want to do your work well, you must first sharpen your tools." Zhikai CNC will help you gain a competitive advantage in the market!