Exploring the automotive industry: How large machine tools use wire EDM to precision-cast engine blocks

In the field of precision manufacturing in the automotive industry, precision hole machining of engine blocks is an art. And large machine tool EDM wire cutting technology is the hero behind this art feast. Today, let us find out how Zhikai CNC helps with precision machining of automotive parts.

1. Application of large machine tool EDM wire cutting in the automotive industry

In the automobile manufacturing process, the precision hole processing of the engine block has extremely high technical requirements. The following are several key parts, whose production cannot be separated from the support of large machine tool EDM wire cutting technology:

Engine block: As the core component of the car, the precision hole processing of the engine block directly affects the performance and life of the engine.

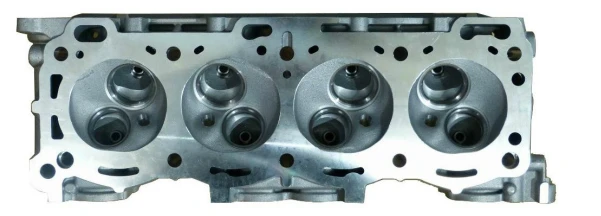

Cylinder head: Precision hole processing such as injection holes and spark plug holes on the cylinder head has extremely high requirements on cutting accuracy and surface quality.

2. Processing difficulties and Zhikai CNC's solutions

Precision requirements: The precision hole machining accuracy of the engine cylinder block is required to be at the micron level. Zhikai CNC's large-scale machine tool EDM wire cutting machine adopts high-precision servo system and advanced control system to ensure machining accuracy.

Surface quality: The surface quality of precision holes directly affects the performance of the engine. Zhikai CNC's cutting technology can effectively reduce surface roughness and improve product quality.

Processing efficiency: The production cycle of automobile parts is short, and high processing efficiency is required. Zhikai CNC's machine tools have high-speed cutting functions, which greatly improves production efficiency.

3. Zhikai CNC: A technological innovator leading the industry

In the automotive industry, Zhikai CNC has become a leader in the industry with the following advantages:

Focus on R&D: Zhikai CNC has always been committed to technological innovation to provide customers with more efficient and stable cutting solutions.

Perfect after-sales service: Zhikai CNC provides a full range of after-sales services to ensure that customers have no worries.

Here are our recommended cutting methods for other automotive parts:

Gears: In response to the precision machining needs of gears, Zhikai CNC provides professional cutting technology and equipment to ensure the machining quality of gears.

Suspension system parts: The shapes of suspension system parts are complex. Zhikai CNC's machine tools have powerful programming capabilities and can easily handle the processing of various complex shapes.

Summarize:

"Precision work, Zhikai CNC." In the field of precision hole processing of engine cylinders in the automotive industry, Zhikai CNC's large machine tool EDM wire cutting technology provides a strong guarantee for the production of high-quality parts. In the future, Zhikai CNC will continue to deepen technology research and development, and promote the vigorous development of the automotive industry with high-quality products and perfect services. Join hands with Zhikai to create brilliance!