Uncovering the secrets of the aerospace industry: How large CNC wire-cutting machines help manufacture precision parts

In the aerospace field that pursues extreme precision, every component is related to flight safety, and large CNC spark wire cutting machines play a vital role in this. Today, let us reveal how an aerospace company uses Zhikai CNC's large CNC spark wire cutting machines to manufacture precision parts for satellite antennas.

1. Application of large CNC spark wire cutting machine tools in the aerospace field

In the aerospace field, the precision parts of satellite antennas have extremely high requirements for processing accuracy and surface quality. The following parts cannot be manufactured without the help of large CNC spark wire cutting machines:

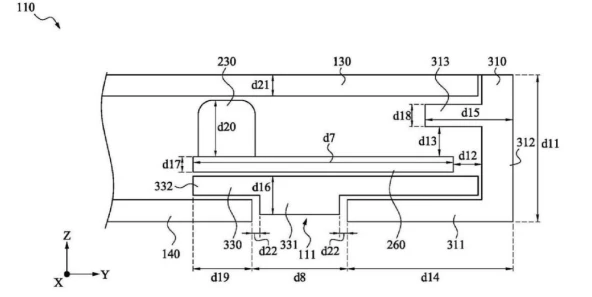

Antenna frame: As the supporting structure of the satellite antenna, the processing accuracy of the antenna frame directly affects the performance of the antenna. Large CNC spark wire cutting machines can achieve high-precision and high-complexity cutting to ensure the accuracy of the antenna frame.

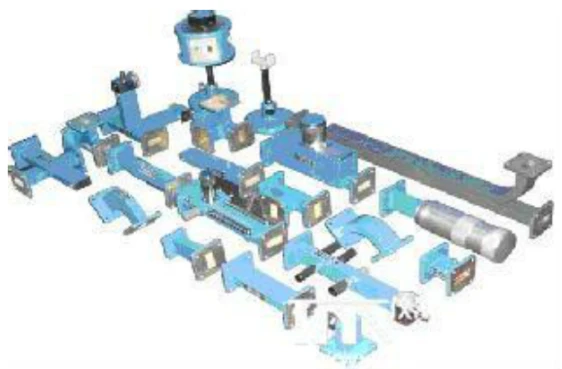

Waveguide components: Waveguide components are key components in satellite antennas. They have complex internal structures and are difficult to process. Large CNC spark wire cutting machines can effectively meet these challenges and ensure the accuracy and performance of waveguide components.

Microwave devices: Microwave devices have extremely strict requirements on size and shape. Large CNC spark wire cutting machines can achieve precision processing to meet the high standards of microwave devices.

2. Processing Difficulties and Solutions

Processing accuracy: The precision requirements for parts in the aerospace field are extremely high. Large CNC spark wire cutting machines achieve high-precision processing by adopting high-precision guide rails, servo systems and advanced control systems.

Surface quality: The surface quality of parts directly affects their service life and performance. Zhikai CNC's large-scale CNC spark wire cutting machine adopts special technology to effectively reduce the surface roughness during the cutting process.

Complex shapes: Satellite antenna components have complex shapes. Large CNC spark wire cutting machines have powerful programming functions and can easily handle the processing of various complex shapes.

3. Zhikai CNC: A trustworthy partner

In the field of aerospace, Zhikai CNC has won the trust of many customers with its strong R&D capabilities and perfect service system. The following are the cutting solutions we recommend for other parts:

Engine blades: We use Zhikai CNC's large-scale CNC spark wire cutting machine to achieve high-precision and high-efficiency processing of blades.

Aviation structural parts: In response to the processing needs of aviation structural parts, Zhikai CNC provides customized cutting solutions to ensure product performance.

Summarize:

"Precision manufacturing comes from Zhikai." In the field of aerospace, large CNC spark wire cutting machines provide a strong guarantee for the manufacturing of precision parts for satellite antennas. Zhikai CNC will continue to deepen its technology research and development, and help my country's aerospace industry take off with better products and perfect services. Join hands with Zhikai to create a better future!