Precision parts for armored vehicles: Large molybdenum wire cutting machine processing in military equipment

In the field of military equipment manufacturing, precision parts for armored vehicles are the core to ensure the performance and reliability of equipment. These parts not only need to withstand high-intensity impacts in extreme environments, but also must meet extremely high precision requirements. So, how are these precision parts made? What role does the large molybdenum wire cutting machine play in this? This article will explore this topic in depth, and combine actual cases to reveal Zhikai CNC's technical advantages and service value in this field.

Challenges in manufacturing precision parts

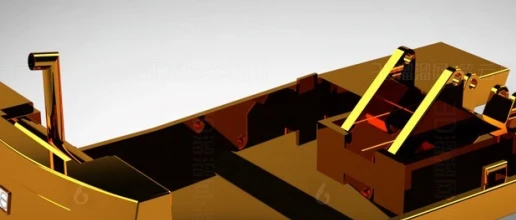

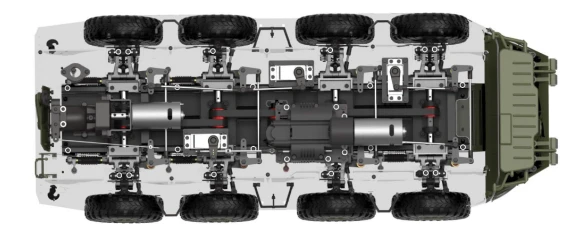

Precision parts for armored vehicles include turret bases, transmission gears, suspension system components, etc. These parts are usually made of high-strength alloy steel, titanium alloy or special composite materials, with complex geometries and strict tolerance requirements. For example, the turret base needs to withstand huge dynamic loads while ensuring dimensional accuracy at the micron level. Traditional processing methods are difficult to meet these requirements, and large molybdenum wire cutting machines have become key equipment to solve these problems.

Large molybdenum wire cutting machine tools use the principle of electric spark discharge and a high-precision control system to cut parts of complex shapes. Its advantage is that it can process high-hardness materials without being limited by the mechanical properties of the materials. At the same time, it can also achieve extremely high surface finish and dimensional accuracy, which is very suitable for precision parts processing in the field of military equipment.

Product analysis of case customers

Taking a military equipment company as an example, in the production of precision parts for armored vehicles, large molybdenum wire cutting machines are widely used in the processing of the following parts:

1. Turret base The turret base is the core component of the armored vehicle firepower system. Its internal structure is complex and requires the processing of a large number of special-shaped holes and precision grooves. Due to the high hardness of the material, traditional processing methods are prone to severe tool wear, while large-scale molybdenum wire cutting machines can easily cope with this challenge and ensure processing accuracy and efficiency.

2. Transmission system gears Transmission system gears have extremely high requirements for dimensional accuracy and surface quality. Any slight error may cause transmission failure. Large molybdenum wire cutting machines can achieve high-precision cutting to ensure the dimensional consistency and surface finish of gears.

3. Suspension system components Suspension system components need to withstand high-frequency vibration and impact loads, so the fatigue strength and processing accuracy of the material are extremely high. Large molybdenum wire cutting machines can complete the processing of complex shapes without affecting the material properties, ensuring the long-term reliability of the parts.

According to statistics, after using Zhikai CNC's large molybdenum wire cutting machine, the customer's production efficiency increased by 25%, and the product qualification rate reached more than 99.8%. This data fully proves the excellent performance of Zhikai CNC equipment in the field of military equipment.

Processing Difficulties and Solutions

In the processing of precision parts for armored vehicles, the following difficulties are faced:

1. High material hardness Military equipment parts are usually made of high-strength alloy steel or special materials, which are difficult to cut efficiently by traditional processing methods. Large molybdenum wire cutting machines can easily process high-hardness materials through the principle of electric spark discharge.

2. Complex shapes Many parts have complex geometric shapes, and traditional machine tools are difficult to achieve high-precision processing. Large molybdenum wire cutting machine tools are equipped with high-precision control systems, which can achieve precise cutting of complex shapes.

3. High surface quality requirements Military equipment parts have extremely high requirements for surface finish, and any tiny flaws may affect performance. Large molybdenum wire cutting machines can achieve high surface quality and reduce subsequent processing steps.

Zhikai CNC's large molybdenum wire cutting machine effectively solves these difficulties by optimizing discharge parameters and control systems, providing customers with efficient and reliable processing solutions.

Zhikai CNC: Leading technology, perfect service

As an industry-leading CNC equipment manufacturer, Zhikai CNC has always been committed to technological innovation and research and development. Our large molybdenum wire cutting machine tools are not only suitable for the field of military equipment, but also widely used in high-precision industries such as aerospace and energy equipment. For example, in the field of aerospace, our equipment is used to process high-precision parts such as engine blades; in the field of energy equipment, our equipment is used to process key parts such as nuclear reactor components.

The advantages of Zhikai CNC are not only reflected in the performance of the equipment, but also in the perfect after-sales service system. We provide customers with all-round support from equipment selection, process optimization to after-sales maintenance to ensure that customers can give full play to the maximum value of the equipment.

Summarize

In the manufacturing process of precision parts for armored vehicles, large molybdenum wire cutting machines are indispensable key equipment. They not only solve the processing problems of high-hardness materials, complex shapes and high surface quality, but also greatly improve production efficiency and product qualification rate. As an industry expert said: "Precision determines performance, and performance determines victory." With its leading technology and perfect services, Zhikai CNC has become a trusted partner in the military equipment industry.

If you are looking for high-precision and high-efficiency processing solutions, Zhikai CNC will be your best choice. We look forward to working with you to jointly promote the high-quality development of the military equipment industry!