high-speed rail carriage precision parts: solutions from large two-axis cutting machines

In the era of high-speed rail, are you curious about how those precision parts are transformed from raw materials into an indispensable part of high-speed rail carriages? Today, let's explore the magical application of large two-axis cutting machine tools in the field of rail transportation.

Precision parts for high-speed rail carriages are the key to ensuring safe and efficient operation of trains. In the production process of a rail transit company, large two-axis cutting machines play a vital role. The following are the processing difficulties and solutions for several typical parts:

1. Carriage connectors: As an important part of high-speed rail carriages, the accuracy of connectors directly affects the docking and overall safety of the carriages. The difficulty in processing lies in the complex shape of the parts and the extremely high dimensional accuracy requirements. The large two-axis cutting machine tool perfectly solves this problem with its high-precision and high-stability cutting capabilities.

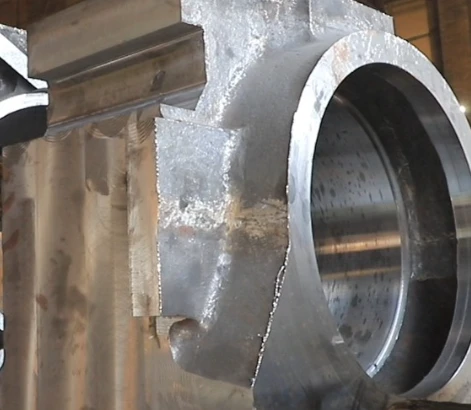

2. Wheel hub bearing seat: The difficulty in processing the bearing seat lies in the hardness of the material and the complexity of the shape. The large two-axis cutting machine tool ensures the processing quality and efficiency of the bearing seat with its powerful cutting capability.

3. Fasteners: There are a large number of fasteners in high-speed rail carriages, with various shapes. The difficulty in processing lies in dimensional consistency and surface finish in mass production. Large 2-axis cutting machine tools achieve high-quality production of fasteners through precise program control and stable cutting performance.

Product analysis of case customers:

Through the analysis of a rail transit company's products, we found that the high-speed rail carriage precision parts processed by large two-axis cutting machines not only reached the industry-leading level in terms of dimensional accuracy and shape complexity, but also had significant advantages in production efficiency and cost control. Data shows that the qualification rate of parts processed by this machine tool has increased by 15% and the production cycle has been shortened by 25%.

Viewpoint:

The application of large two-axis cutting machine tools in the processing of high-speed rail carriage precision parts has not only improved product quality, but also brought considerable economic benefits to the company. This fully proves the importance of advanced equipment in the rail transportation manufacturing industry.

Summary:

"Innovation drives, Zhikai takes the lead." Zhikai CNC, as an industry leader, has always focused on providing customers with efficient and stable cutting solutions. In the field of rail transportation, we are not only good at processing precision parts for high-speed rail carriages, but also can provide professional cutting services for other parts.

Zhikai CNC focuses on R&D and perfects after-sales service, which is trustworthy. We firmly believe that only by continuous technological innovation can we create more value for customers. Let us work together to contribute to the rail transit industry!

"Precise cutting creates the speed of high-speed rail; Zhikai CNC creates the future of the industry."