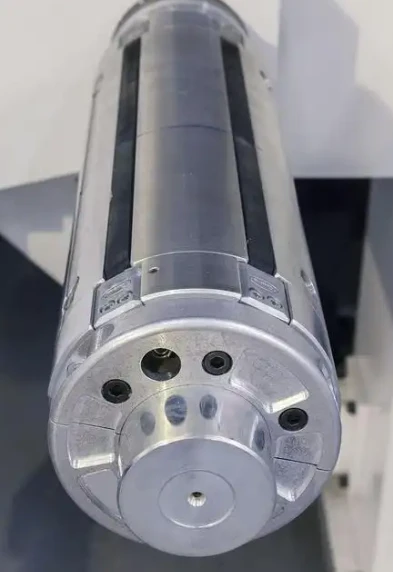

Unveiling the fine processing techniques of printing press cylinders: C-type six-axis medium-speed wire cutting machine tool demonstrates its prowess

In the printing machinery industry, the fine processing of rollers is the key to improving printing quality. Today, we will deeply explore the application of C-type six-axis medium-speed wire cutting machine tools in the fine processing of printing machine rollers, as well as the challenges faced in this process, bringing a new perspective to industry peers.

1. Case Customer Product Analysis

The fine processing of printing press cylinders has a decisive influence on the printing quality. The following are some key points when processing printing press cylinders with a C-type six-axis medium-speed wire cutting machine:

Analysis of processing difficulties

Precision requirements: The surface roughness and shape accuracy of the roller are extremely high, which directly affects the printing effect.

Material characteristics: The roller material is mostly alloy steel with high hardness, which is difficult to process.

Complex patterns: The drum surface often needs to be processed into complex patterns, which places higher requirements on the performance of the machine tool.

Application of C-type six-axis wire cutting machine tool

High-precision machining: The C-type six-axis medium-speed wire cutting machine, with its high precision and high stability, perfectly meets the needs of fine machining of rollers.

Complex pattern processing: Six-axis linkage technology enables the machine tool to easily process complex roller patterns.

2. Case Customer Data and Views

Through the analysis of production data of a printing machinery company, we found that the product qualification rate of rollers processed by C-type six-axis medium-speed wire cutting machine tools increased by 15% and production efficiency increased by 20%. The customer company said that the introduction of C-type six-axis medium-speed wire cutting machine tools not only improved product quality, but also reduced production costs.

3. Advantages and recommendations of Zhikai CNC

As a leading enterprise in the industry, Zhikai CNC has been committed to the research and development and innovation of medium-speed wire cutting machine tools. The following are some of our advantages:

Focus on R&D: Zhikai CNC has a professional R&D team that continuously optimizes product performance to meet market demand.

Perfect after-sales service: We provide a full range of after-sales services, including equipment installation, commissioning, training, after-sales maintenance, etc., to ensure that customers have no worries.

In addition, Zhikai CNC also recommends cutting for the following parts:

Mould industry: suitable for the processing of various precision moulds, such as stamping moulds, plastic moulds, etc.

Aerospace: Suitable for high-precision parts processing in the aerospace field.

Summarize

The C-type six-axis wire-cut machine tool plays an important role in the fine processing of printing machine cylinders. Zhikai CNC has won the trust of customers with its strong R&D strength and perfect service system. As a golden sentence says: "Innovation leads the future, quality creates brilliance." Choose Zhikai CNC, let us jointly promote the development of the printing machinery industry!