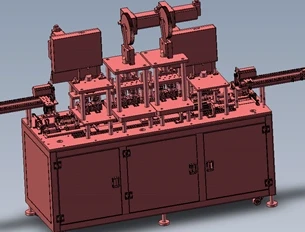

Precision components for sealing machines, packaging machinery and C-type four-axis cutting equipment machine tool processing

In the field of packaging machinery, the sealing machine is the "gatekeeper" that ensures the sealing and integrity of the product. The accuracy and stability of its operation are completely dependent on the high quality of the internal precision components. In the processing of these precision components, the C-type four-axis cutting equipment machine tool plays an irreplaceable role. Today, let us explore the mystery of it and see how it helps packaging machinery companies overcome processing problems.

Take a packaging machinery company as an example. In the production and manufacturing of sealing machines, multiple precision components need to be processed with the help of C-type four-axis cutting equipment machine tools. Among them, the heat sealing knife seat is one of the key components. When the heat sealing knife seat is working, it is necessary to ensure that the heat sealing knife is accurately pressed down to achieve seamless heat sealing of the packaging material. This requires that the installation hole position of the heat sealing knife seat is extremely accurate, and the hole spacing error must be controlled within ≤±0.00 6 mm. Once the hole position deviates, the heat sealing knife will tilt during operation, resulting in loose packaging sealing, and the product is extremely susceptible to moisture and deterioration. With its precise control capability of four-axis linkage, the C-type four-axis cutting equipment machine tool can accurately process the complex hole system structure on the heat sealing knife seat, ensure the position accuracy and aperture size accuracy of each hole, and provide solid guarantee for the stable installation of the heat sealing knife.

Let's look at the transmission cam of the sealing machine, which is also an extremely important precision component. The transmission cam is responsible for converting the rotational motion of the motor into the reciprocating linear motion of the sealing machine's actuator. The accuracy of its contour curve directly affects the accuracy and stability of the sealing action. The error of the cam contour curve must be controlled within ≤±0.00 3 mm, otherwise the sealing machine will have problems such as inconsistent sealing time and uneven sealing force during operation, which will seriously affect the packaging quality. The C-type four-axis cutting equipment machine tool uses advanced CNC programming to accurately control the movement trajectory of the electrode wire according to the complex cam contour design, cut out a high-precision cam contour, and ensure the efficient and stable operation of the sealing machine.

There are many challenges in processing these precision components of the sealing machines. First of all, in order to ensure the durability and hygienic safety of the sealing machines, precision components are mostly made of high-quality stainless steel or special alloy materials. These materials have high hardness and strong toughness, and it is difficult for ordinary processing equipment to achieve high-precision cutting. The C-type four-axis cutting equipment machine is equipped with a high-performance pulse power supply and advanced cutting technology, which can effectively overcome the processing difficulties caused by material hardness. Secondly, the complex shape and strict precision requirements of precision components place extremely high demands on the motion control and stability of the processing equipment. Zhikai CNC's C-type four-axis cutting equipment machine uses high-precision ball screws and linear guides, and with the independently developed high-performance CNC system, it can achieve a positioning accuracy of ≤±0.00 6 mm, meeting the processing needs of precision components of the sealing machine.

Zhikai CNC always adheres to the concept of "innovation drives development, quality wins the future". In terms of research and development, we continue to invest a lot of resources, cooperate with the industry's top scientific research institutions, and continuously optimize the performance of C-type four-axis cutting equipment machine tools. At the same time, we have established a complete after-sales service system to provide customers with all-round support from equipment installation and commissioning, operation training to after-sales maintenance, so that customers have no worries. As the golden sentence says: "Professionalism achieves quality, and service creates reputation." For other parts in the packaging machinery industry, such as valve components of filling machines, positioning sliders of labeling machines, etc., Zhikai CNC's C-type four-axis cutting equipment machine tools can also provide excellent cutting solutions. Choosing Zhikai CNC means choosing a more efficient and precise processing partner to help packaging machinery companies improve product quality and stand out in market competition.