Precision parts for printers: office equipment and large three-axis cutting machine tool processing

In the field of office equipment manufacturing, the processing quality of precision parts directly determines the performance and stability of the equipment. As office equipment develops towards high precision and multi-functions, traditional processing methods can no longer meet the manufacturing needs of complex and precision parts. The emergence of large three-axis cutting machines provides a new solution for high-precision parts processing of office equipment. Today, we take an office equipment company as an example to explore in depth the application and difficulties of large three-axis cutting machines in the processing of precision printer parts.

Case: Challenges in processing precision parts for printers

A certain office equipment company is a leading domestic printer manufacturer, and its products are known for their high precision and high reliability. However, as the market's requirements for printer performance increased, the company encountered many processing difficulties during the production process, especially in the manufacturing of some precision parts.

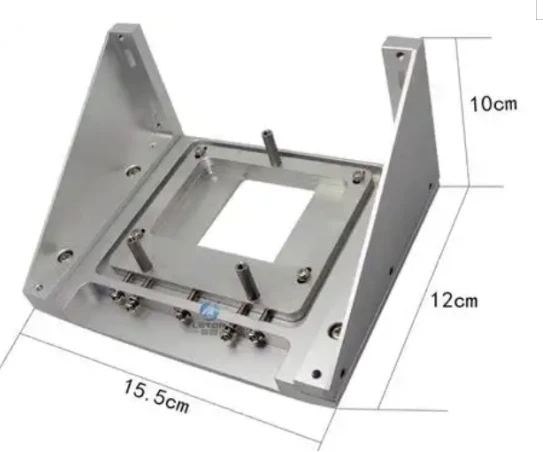

1. Print head bracket

The print head bracket is a key component used to fix the print head in the printer. Its dimensional accuracy and surface finish directly affect the printing quality. The print head bracket is usually made of high-strength aluminum alloy material, and traditional processing methods are prone to deformation and insufficient precision. The large three-axis cutting machine tool can achieve micron-level processing of the print head bracket through high-precision cutting technology, ensuring its dimensional accuracy and surface quality.

Processing difficulties:

- The material is very hard, and traditional processing methods are inefficient and cause severe tool wear.

- Extremely high dimensional accuracy is required (error ≤ ±0.00 3 mm).

- Stress deformation is easily generated during the processing, affecting the stability of the parts.

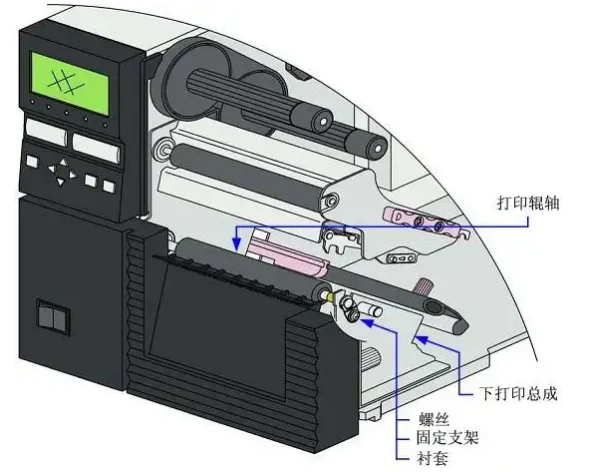

2. Paper feed roller

The paper feed roller is a key component in the printer for controlling paper feeding. Its surface accuracy and shape accuracy directly affect the feeding stability of the paper. The paper feed roller usually needs to be machined with complex groove structures, which require extremely high dimensional accuracy and surface finish. Large three-axis cutting machines can achieve high-precision machining of complex grooves to ensure the performance stability of the paper feed roller.

Processing difficulties:

- The groove structure is complex and it is difficult to achieve high precision using traditional processing methods.

- Extremely high surface finish is required (Ra ≤ 0.7-1.4 μm).

- Thermal deformation and stress concentration of materials must be avoided during processing.

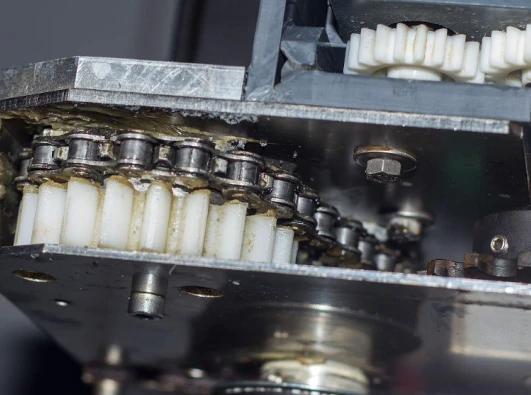

3. Transmission gear

Transmission gears are important components for transmitting power in printers. Their tooth profile accuracy and surface quality directly affect the smooth operation of the equipment. Transmission gears are usually made of high-hardness alloy materials. Traditional processing methods are difficult to meet the requirements of high hardness and high precision. Large three-axis cutting machines can effectively avoid material damage and achieve high-precision cutting through non-contact processing.

Processing difficulties:

- High tooth profile accuracy requirements (error ≤ ±0.00 3 mm).

- Requires extremely high surface finish and wear resistance.

- Micro cracks on the material surface must be avoided during processing.

Advantages of Large 3-axis Cutting Machine Tools

In the above case, the large three-axis cutting machine tool demonstrated its unique advantages in the processing of precision parts for printers:

1. High precision: It can achieve micron-level processing accuracy and meet the stringent requirements of precision parts.

2. High efficiency: Through the automated control system, production efficiency is greatly improved and labor costs are reduced.

3. Strong adaptability: It can process parts with high hardness and complex shapes, solving the limitations of traditional processing methods.

4. High stability: Advanced cooling technology and stress release process effectively avoid deformation and material damage during processing.

Zhikai CNC: Win trust with R&D and after-sales service

As a leading domestic CNC equipment manufacturer, Zhikai CNC has always been committed to providing customers with high-precision and high-efficiency processing solutions. In addition to large three-axis cutting machines, Zhikai CNC has also launched a variety of processing equipment suitable for the office equipment industry, such as high-precision CNC milling machines, five-axis linkage machining centers, etc., which can meet the processing needs of different precision parts.

The core advantages of Zhikai CNC:

1. Focus on R&D: We invest a lot of resources in technology research and development every year to ensure that our products are always at the leading level in the industry.

2. Improve after-sales service: We have established a nationwide after-sales service network to provide customers with timely and professional technical support.

3. Customized solutions: Provide personalized processing solutions according to customer needs to help customers improve production efficiency and product quality.

Summarize

In the office equipment industry, the processing quality of precision parts is the core guarantee of equipment performance. Large three-axis cutting machine tools, with their advantages of high precision and high efficiency, have become an ideal choice for the processing of precision parts for printers. Zhikai CNC provides customers with reliable processing solutions with its strong R&D capabilities and perfect after-sales service. As an industry expert said: "Precision machining is the soul of office equipment, and Zhikai CNC is the creator of this soul."

If you are also troubled by the processing problems of precision printer parts, you may wish to contact Zhikai CNC. We will provide you with the most professional solutions to help you stand out from the competition!