Metal parts processing of automatic packaging machines: Analysis of the application of large-scale micro-wire EDM machines in the packaging machinery industry.

In the packaging machinery industry, the metal parts of automatic packaging machines are the core elements that determine the performance and service life of the equipment. As the market's requirements for packaging efficiency, precision and stability become higher and higher, how to efficiently and accurately process these metal parts has become the focus of the industry. Large-scale micro-electric spark wire cutting machine tools (hereinafter referred to as "wire cutting machine tools") are the key equipment to solve this problem. Today, we will deeply explore the application of wire cutting machine tools in the processing of metal parts of automatic packaging machines, and how Zhikai CNC helps industry customers break through processing bottlenecks through technological innovation and high-quality services.

Difficulties in processing metal parts of automatic packaging machines

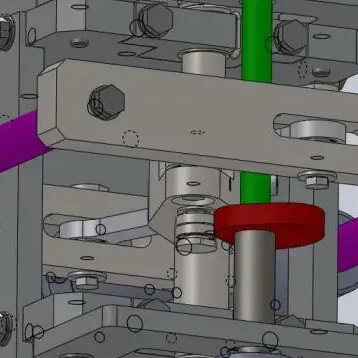

There are many kinds of metal parts in automatic packaging machines, including precision gears, cams, blades, molds, etc. These parts are not only complex in shape, but also have extremely high requirements for dimensional accuracy, surface finish and material hardness. The following are the processing difficulties of several typical parts:

1. Precision gears: Gears are the core components of the automatic packaging machine transmission system, and their tooth profile accuracy directly affects the running stability and noise level of the equipment. Traditional processing methods are difficult to meet the requirements of micron-level precision, and are prone to tool wear due to the high hardness of the material.

2. Cam mechanism: The cam has a complex profile and requires high-precision curve control during processing. Any carelessness will affect the coordination of the packaging machine's movements.

3. Blades and molds: The blades and molds of automatic packaging machines are usually made of high-hardness alloy materials. Traditional cutting processing is inefficient and costly, while wire cutting machines can easily cope with the processing needs of these materials.

These difficulties place extremely high demands on processing equipment, and large-scale micro wire-cut EDM machines, with their high precision, high stability and wide material adaptability, have become an ideal choice for solving these problems.

Case customer: Application of wire cutting machine tools in the processing of metal parts of automatic packaging machines

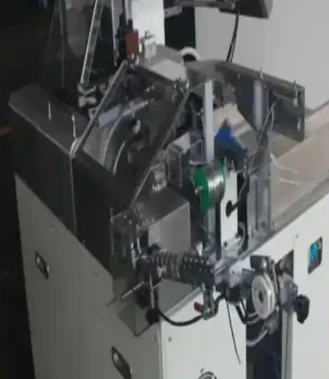

A certain packaging machinery company is a long-term partner of Zhikai CNC. The automatic packaging machines it produces are known for their high efficiency and stability. In the company's production process, wire cutting machines are widely used in the processing of the following parts:

1. Precision gear processing: The company uses Zhikai CNC's large-scale wire cutting machine tools to process gears, with an accuracy of ≤±0.00 3 mm and a surface roughness of Ra ≤ 0.7-1.4 μm, which significantly improves the transmission efficiency and durability of the gears.

2. Cam profile processing: Through Zhikai CNC's micro wire cutting machine, the company has achieved one-time forming processing of complex cam profiles, improving processing efficiency by 30% and eliminating the need for subsequent polishing.

3. High-hardness blade processing: The company uses wire cutting machines to process high-hardness alloy blades, which not only avoids the tool wear problem in traditional processing, but also shortens the processing cycle by 40%.

Data shows that after introducing Zhikai CNC's wire cutting machine tools, the company's product qualification rate increased by 15%, production costs decreased by 20%, and customer satisfaction significantly improved.

Zhikai CNC: Win trust with technological innovation and high-quality services

As a leading company in the field of wire-cut EDM machines, Zhikai CNC always adheres to customer demand-oriented approach and is committed to providing efficient and precise processing solutions for the packaging machinery industry.

1. Focus on R&D and lead the technological frontier: Zhikai CNC invests 10% of its sales revenue in R&D every year and has launched a number of large-scale micro wire cutting machine tools suitable for different processing scenarios. For example, in response to the high-hardness material processing needs of metal parts of automatic packaging machines, Zhikai CNC has developed a special electrode wire and intelligent control system to further improve processing efficiency and precision.

2. Improve after-sales service to solve customer worries: Zhikai CNC has established a complete after-sales service network across the country, providing full-process support from equipment installation, commissioning to operation training. In addition, Zhikai has also launched a remote diagnosis service to help customers quickly solve problems in equipment use.

Summarize

"In the packaging machinery industry, the metal parts of the automatic packaging machine are the heart of the equipment, and the wire cutting machine is the precision scalpel that shapes this heart." With its leading technical strength and thoughtful after-sales service, Zhikai CNC has become the preferred partner for many packaging machinery companies.

If you are looking for a wire cutting machine that can meet the needs of high-precision and high-efficiency processing, Zhikai CNC will be your trustworthy choice. Whether it is precision gears, complex cams, or high-hardness blades, Zhikai CNC can provide you with customized solutions to help your company stand out in the fierce market competition!