CNC wire cutting machine tools: spacecraft parts processing solutions for the aerospace industry

Recently, we have received some inquiries from customers in the aerospace industry, who expressed their needs for spacecraft parts processing. In the aerospace field, the reliability of spacecraft parts is crucial to the operation and safety of the entire spacecraft. As a high-precision processing equipment, CNC wire cutting machine tools can meet the complex processing requirements of spacecraft parts and provide a strong guarantee for the precise processing of parts.

1. Processing Principle The CNC wire cutting machine uses the discharge sparks generated between the electrode wire and the workpiece to erode the material, thereby realizing the processing of spacecraft parts. By precisely controlling the movement trajectory and discharge parameters of the electrode wire, the required shape and size of the parts can be accurately cut. During the processing, the electrode wire forms a discharge channel with the surface of the workpiece under the action of the pulse power supply, instantly releasing high temperature and high pressure energy, causing the material to melt and vaporize rapidly. At the same time, by adjusting the feed speed and cutting direction of the machine tool, fine processing of parts can be achieved.

2. has very strict processing standards for spacecraft parts. For example, the dimensional accuracy of the parts is high, and the tolerance is usually controlled within ±0.008 mm ; the surface roughness is required to be below Ra0.8μm to ensure the surface quality and performance of the parts. In addition, the material of the parts must meet the relevant quality standards and have good mechanical properties and high temperature resistance.

3. Processing equipment

1、Zhikai CNC Wire Cutting Machine Tool

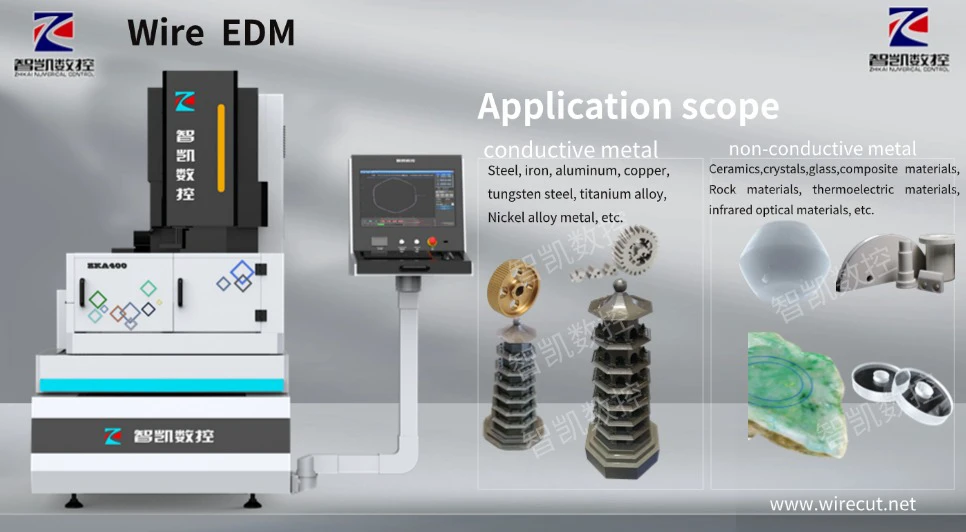

Equipment Overview: Zhikai CNC wire cutting machine is a high-precision processing equipment specially designed for the aerospace industry. It adopts an advanced CNC system to achieve precise control of the processing of spacecraft parts. The machine is equipped with a high-performance pulse power supply and high-quality electrode wire to ensure the stability and accuracy of processing. At the same time, the machine also has a good operating interface and convenient operation mode, which can meet various needs of parts processing.

Equipment features: Zhikai CNC wire cutting machine tools have the characteristics of high precision, high stability and high efficiency. Its processing accuracy can reach ±0.0 08 mm, which can meet the high-precision processing requirements of spacecraft parts. The machine tool adopts advanced discharge technology and optimized processing technology, which can effectively improve processing efficiency and shorten processing cycle. In addition, the machine tool also has good reliability and safety, which can ensure the smooth progress of the processing process.

Commonly used cutting electrodes : The commonly used cutting electrodes for Zhikai CNC wire cutting machines are molybdenum wires, etc. Molybdenum wires have good conductivity and corrosion resistance, and can maintain a stable discharge state during processing to ensure processing accuracy.

Test case display: In the actual processing process, Zhikai CNC wire cutting machine successfully processed spacecraft parts for many aerospace companies. By precisely controlling the processing parameters and optimizing the processing technology, the processed parts have high dimensional accuracy and good surface quality, which has been highly recognized by customers.

2、Processing

① Parts Preparation

Part design drawings: Design drawings of parts based on customer requirements and the characteristics of spacecraft parts. The drawings should include detailed information such as the shape, size, and precision requirements of the parts.

Material preparation: Select suitable part materials, such as aluminum alloy, titanium alloy, etc. The material should have good mechanical properties and processing properties to ensure the quality and service life of the parts.

Tool preparation: Prepare the tools needed to process parts, such as cutting, clamping, measuring instruments, etc. The tools should have good accuracy and reliability to ensure the smooth progress of the processing.

② Parts processing

Cutting process: Fix the part material on the machine tool workbench, start the machine tool, and the electrode wire begins to cut the part material according to the predetermined cutting path. During the cutting process, the machine tool control system will automatically adjust the movement trajectory and discharge parameters of the electrode wire according to the processing requirements to ensure the cutting accuracy and quality.

Processing completed: When the cutting is completed, the part material is processed into the required shape and size. At this time, the machine tool will automatically stop processing and remove the processed part from the workbench.

Quality inspection: Carry out quality inspection on processed parts, including dimensional accuracy, surface roughness, hardness, etc. to ensure that the quality of parts meets relevant standards.

Surface treatment: Surface treatment of parts, including cleaning, polishing, coating, etc. Improve the surface quality and performance of parts.

Packaging: Pack the processed parts for transportation and storage.

Through the above processing flow, Zhikai CNC wire cutting machine can provide efficient and precise solutions for the processing of spacecraft parts in the aerospace industry. If you have a deeper interest in the use videos, diagrams, operation steps, precautions, work instructions, operating specifications, CNC wire cutting machine operation specifications, usage methods, test videos and principles, and related technologies and applications for spacecraft parts processing, you are welcome to continue to follow us. You can also contact us by private message or message. The marketing team of [ Zhikai CNC ] will continue to update you with the application skills and solutions of CNC wire cutting machine in the processing of spacecraft parts in the aerospace industry.