Upgraded the High Frequency System

Exclusive non-resistances &Non- Electrolysis High Frequency power supply, single cutting speed up to 12,000 square per hour,3 times cutting, the best roughness can be up to Ra0.6μm.Non-electrolysis power processing alloy does not change color. non-resistances High frequency also saves 60% power, only 0.4KW/H.

Lower Moly-wire consumption

While focusing on research and development to improve efficiency, greatly reduce molybdenum wire wearing, cutting efficiency increased by 30%, molybdenum wire wearing is lower ( 200K MM2/0.01mm wire weared)

Low failure rate, long using life

New electrical cabinet design, non- resistors, low heat, longer using life of electronic components; No fan, reduce cutting water mist into the electrical cabinet.

New CoolCut software, friendly man-machine interface

The latest research and development of Coolcut control software, based on Windows 10 64-bit platform, Ethernet interface, high communication rate and better stability. The Servo motor supports up to 50,000 steps. Support pitch compensation and AR rotation

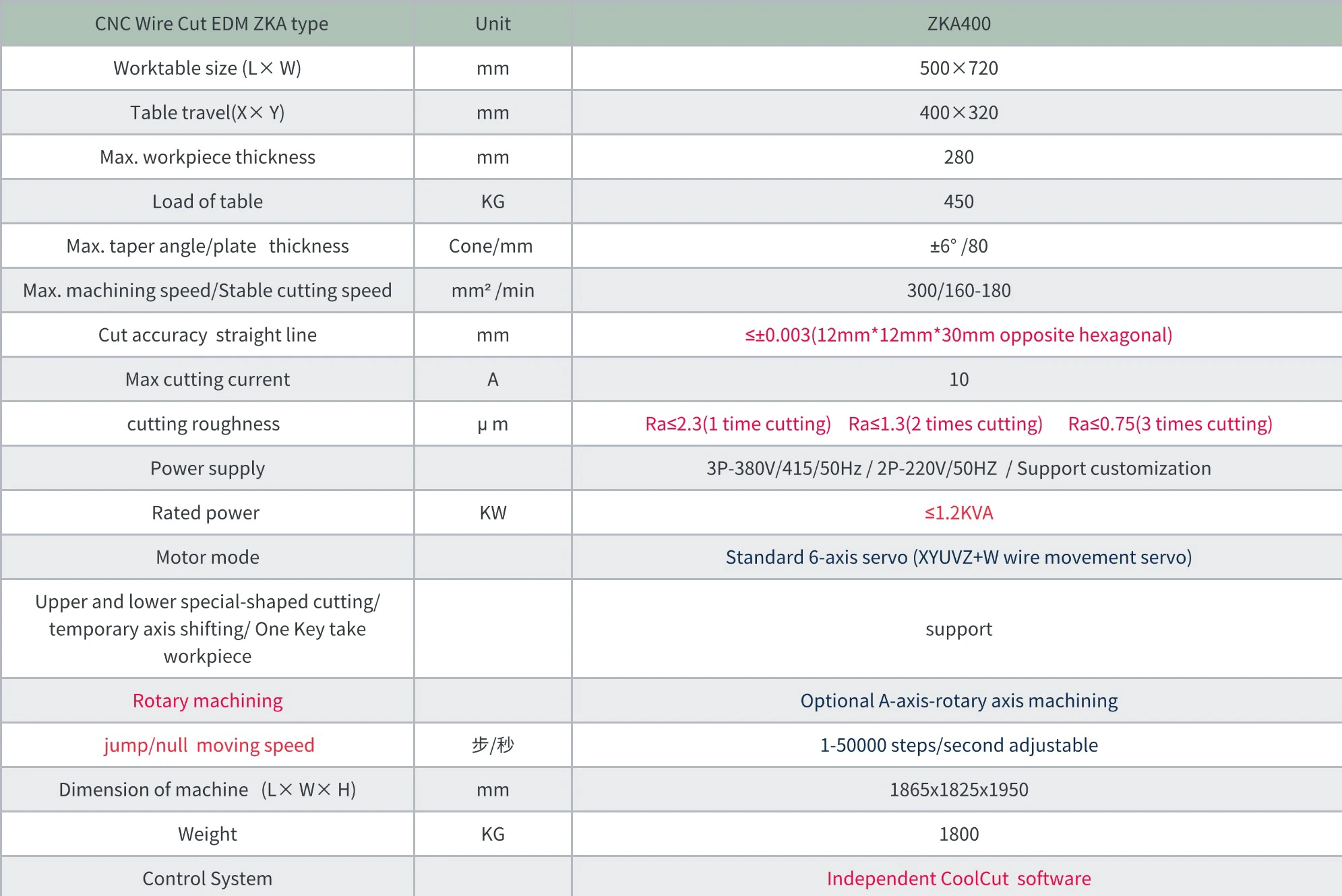

ZKA series specifications

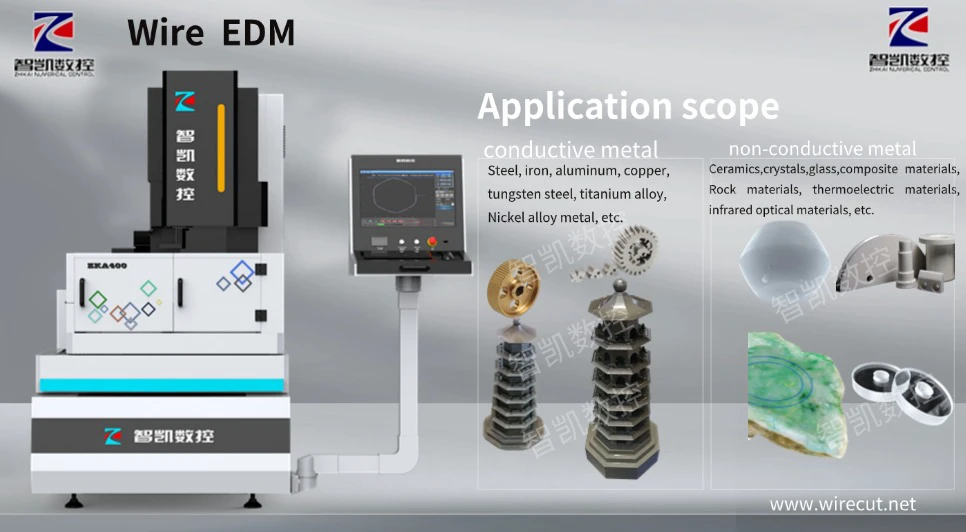

Application field:

ZKA400 is mainly used in various mechanical manufacturing fields, such as automotive manufacturing, aerospace, energy equipment, electronic equipment, etc. Its high precision, efficiency, and reliability make the ZKF450 an ideal choice for various manufacturing enterprises.

We always adhere to the business philosophy of customer-centric and quality oriented. We believe that ZKF450 will be your ideal choice. If you have any questions about our products or need customized services, please feel free to contact us at any time. We look forward to working with you!