1.Introduce

Suzhou Zhikai CNC Technology Co., Ltd. was established in 2011. Its predecessor, Suzhou Longting Electromechanical Technology Co., Ltd., was founded in 2005. The company is mainly engaged in the research, development, production, and sales of wire - cutting programming control software and control circuits.

Over the past nearly 20 years of research and development, with its superb technology and excellent services, Suzhou Zhikai has won unanimous recognition from the industry. To enhance the efficiency of after - sales service and improve the equipment controllability for end - users, the company was founded with a commitment to developing and manufacturing electrical processing equipment that best suits market needs. This includes mid - line cutting, slow - line cutting, diamond - line cutting, fast - line cutting, punching machines, spark machines, etc.

The company boasts a variety of unique products. These include the Cool - Cut Wire Cutting Software with independent technology, six - axis servo - closed - loop wire - cutting machines, five - axis CNC wire - cutting machines, spiral - processing equipment, 360 - degree rotary - processing wire - cutting machine tools, brass slow - wire wire - cutting machines, Drill EDM, Die Sinker EDM, CNC Milling and Engraving, and CNC Machining Centers. Through years of experience accumulation and the recruitment of high - quality scientific and technological talents (with two doctors, several postgraduates, and undergraduates in the R & D department), the company has overcome the drawbacks of traditional wire - cutting machines, such as poor surface roughness, slow speed, and high wire wear.

In 2015, the company launched a non - electrolytic and non - clogging high - frequency system, filling the gap in the domestic non - clogging and non - electrolytic high - frequency system for wire - cutting. The independently developed CoolCut Wire Cutting Control System by Zhikai can achieve 17 - pass wire cutting and process up to 200,000 mm². Its three - pass cutting effect is comparable to that of slow - wire cutting, creating more value for users.

In 2016, the CoolCut Wire Cutting Control System, which is built - in with slow - wire cutting and multiple mainstream functions and features a stable, intelligent, efficient, and user - friendly operation interface, was launched and won unanimous praise from customers.

With more than 20 years of experience in EDM, a 50,000 ㎡ factory area, 50 employees, dozens of honors, and over 15 patents, the company adheres to a strict quality - control process. Each machine undergoes 7 - step inspections by more than 25 quality controllers. The company also implements a 6S management system and a complete product - control system (with a unique ID for each machine for tracking). Over 30,000 machines have been installed in China and more than 60 other countries.

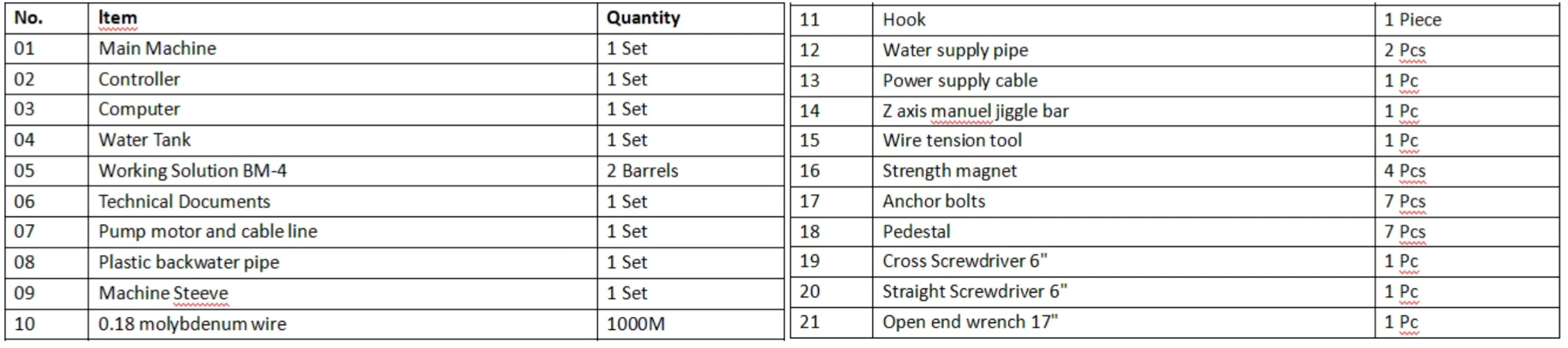

2.Parameter

3.Function

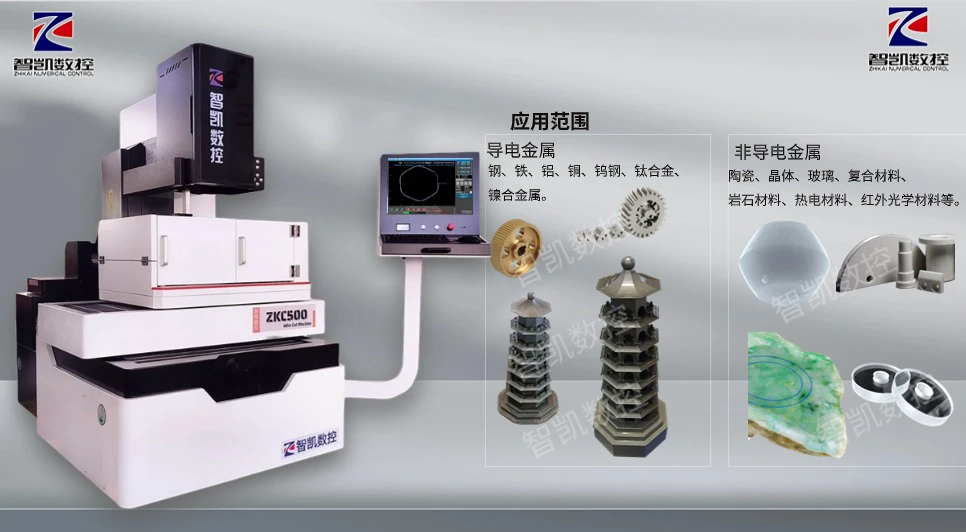

WEDM take wire (Molybdenum wire or Tungsten and Molybdenum alloy wire ) as electrode, working liquid as media, Electrical discharging happened between the electrode and the work piece by using of the high frequency impulse power and the high peak current to bring high heat and high energy to erode the work piece. The preconceived track of the wire is controlled by the moving of X-Y axis and U-Y axis which are driven by the machine. Then the work piece is processed.

"Zhikai CNC" machines featured with beautiful shape, novel structure, superior performance, and convenient operation. Meanwhile they are of good rigidity, small cutting force , big load bearing, steady movement, and safety operation. they are suit to cut the workpiece of high precision, fairly good rigidity, high toughness, especially the cold die, extrusion die, plastic mould, gear cutter hob, precision component (including big taper, same taper, unequal cone, laid abnormity and etc.)

Medium speed wire cut EDM is a new generation of EDM machines which are widely used in the fields of moulds, automobile parts, aeronautics and astronautics, electronic instrument, military, light industry, and household appliances.

4.Feature

The Taper Cutting Mechanism: It's driven by two step-motors to realize U and V movement, which can make the 4 axis (X,Y,U,V) simultaneously movement.

Structure of wire frame:The symmetric structure for the upper and down frame to keep the tension of moly wire within the scope of normal tension. There are same quantity of arrange wire pulley, which make same tension in every point of the moly wire. So no matter thin or thick work piece, the moly wire is not easy to break down. Comparing with "C" Shape structure, which always been used in other factories' machine. Our structure short the wire travel route to avoid the shock during the running of the wire and make sure the accuracy.

The working table: The working table with T-shape slots, we supply a standard clamp for free.

5.Control System

① Controller Layout:

The basic framework of the CoolCut controller adopt professional profiles and connection fixed facilities by the technology from German, the controller has realized both elegant appearance outside and rational layout inside. The effect of sealing, electromagnetic compatibility and heat dissipation is well and the controller must be high temperature aged before being sold to make sure the components be able to work for a long time continuously.

② Computer and Monitor:

Adopt High Performance Industrial computer, P4 or better, 1G RAM, 30G Harddisk, support INTERNET, with LCD Color Monitor.

③ High Frequency Power and the Internal Circuit:

Adopt the digital high frequency power, the power generator is controlled by CoolCut software, which can improve the precision and the stability of the pulse signal and reduce the probability of the high frequency power failure, advance the machining efficiency and the quality of working piece. Max. Current 6A ,max efficiency>=120m2/min, surface roughness<=1.2um. The modular design is used in the internal wiring, which can reduce the probability of the failure, and it's easy to maintain.

Cool system

① New style of three levels filtration tank:

first level: filter cotton, second level: copper mesh, third level: 5um paper filter; can prolong working solution life time and improve both working solution cleanliness and residue discharge ability, so save cost but improve work piece smooth finish ( cooperate using "Baoma" new type working solution is more friendly to operators and environment ). The capacity of the tank is 100L.

② The Cooling Pump:

Adopt import booster pump which is able to work stably long time.

Control system

CoolCut Boot Screen

Using the PCI slot controller card and the High-tech Industrial computer, which greatly enhanced the stability of control and greatly reduced the computer the failure rate.

To achieve a fast and convenient computer communication network, through network technology, graphics, data and program transmission, can be directly controlled by the technical design department since the first establishment of a program.

Embedded Control system can be smoothly connected with many design software such as CoolCut & etc.

The search function of mechanical origin enable the transmission screw pitch compensation, in order to greatly improve the positioning accuracy, especially in Servo control system.

With a large storage capacity database, which accumulated from many experiences. User can choose the suitable parameter according to deferent working conditions. Users can adjust machining parameters to establish a database at any time according to their own experience.

The parameters of pulse power is directly controlled by the software , so as to not only improve anti-jamming capability in pulse power output, but also increase the roughness of work piece and reduce the loss of molybdenum wire.

Pulse power of the control parameters directly from the software to control and improve the ability of pulsed power output of the interference, thereby increasing the roughness of workpiece, reducing the loss of molybdenum wire, you can choose a variety of pulse waveforms for a variety of processing conditions, improve the cutting ability of the workpiece.

Simplifies the operation buttons on the control panel, a large number of button functions directly controlled by software to achieve.

CoolCut Software basic function

Coordinate system: absolute coordinate, incremental coordinate (relative coordinate).

Functions of coordinate transforming, zoom in and zoom out, rotating and tracking display in real time

Functions of interpolation of straight line and circular arc.

Function of taper processing

Function of processing different top and bottom shape

Functions of short circuit and wire-break handling

Functions of memorizing when power was cut and auto-stop after processing

Functions of auto-edge position and auto-centering

Function of auto-adding transitional arc (Arbitrary angle)

Function of processing backward

Functions of menu technology and auto-programming;

Data transmission

functions of multi-cutting

CNC System Configuration and Performances

CNC hardware

Indutrial PC:win10;

1024MB RAM;

256GB hard disk;

19" LCD color display;

USB and INTERNET

CNC software and operating platform:

CNC Auto-program and control function

The operating platform is Windows XP

CNC system technical performance:

CNC 4 axes simultaneously control;

Function of processing different top and bottom abnormities parts

CNC system working environment:

The voltage: 3-phase 380V± (1%-10%), 50Hz (customizing accepted)

Relative humidity: 40%~80%

Cleaning environment, the dust with active gas and precipitation is not allowed; make sure there are no machines making much dust while working.

No vibration source, no electromagnetic wave source in the rang of 20m

6.Package