Why is no one willing to do wire cutting? Is the salary 8,000RMB? Is it easy to learn?

Wire cutting is a highly technical job that usually requires experienced operators and precision wire cutting equipment. However, despite being a critical manufacturing technology, there are some challenges in its practical application that may discourage some people from doing this job.

1. Wire cutting requires highly specialized skills and knowledge. Operators must understand the properties of different types of metals, master the operating principles of various wire cutting equipment, and have a good foundation in mathematics and physics. This high level of specialization may be daunting for some people because they need to spend a lot of time and effort to learn and master these skills.

2. Wire cutting often requires handling complex parts and precision processing requirements. Operators must have a high degree of patience and a meticulous work attitude to ensure that each step is accurately executed. This high level of precision and requirements also discourages some people because they may find this work too tedious and challenging.

3. Wire cutting may require a high level of concentration for a long time. Since any small mistake during the operation may result in damage to the parts or unqualified processing, the operator must always be vigilant. This high level of attention requirement may make some people feel that this work is too tiring and stressful.

4. Wire cutting work may expose workers to a certain degree of danger. Although modern wire cutting equipment is usually equipped with safety measures, operators still need to strictly follow operating procedures to ensure their own safety. This potential danger may also discourage some people from doing this job.

5. Although wire cutting work has certain challenges and difficulties, there are also many people who are willing to do this job. For those who love manufacturing and are keen on technical challenges, wire cutting work is not only a career, but also an interest and pursuit. They are willing to keep learning and constantly challenge themselves in order to achieve better results in this field.

6. In actual production and manufacturing, wire cutting work still plays an irreplaceable role. Many industries, especially in automobile manufacturing, aerospace, electronic equipment and other fields, require precision wire cutting processing to meet the needs of complex parts. Therefore, those with relevant skills and experience are often favored by the market and have good career development prospects.

In general, although wire cutting work has certain difficulties and challenges, there are still many people willing to do it. This is because, for those who love technology, have patience and meticulousness, wire cutting work is not only a profession, but also a pleasure and pursuit. They have made positive contributions to the development of the manufacturing industry by constantly learning and improving their skills. At the same time, with the continuous advancement of technology, the difficulty and risk of wire cutting work are gradually decreasing, which provides opportunities for more people, making more people willing to join this field and jointly promote the development and progress of the manufacturing industry.

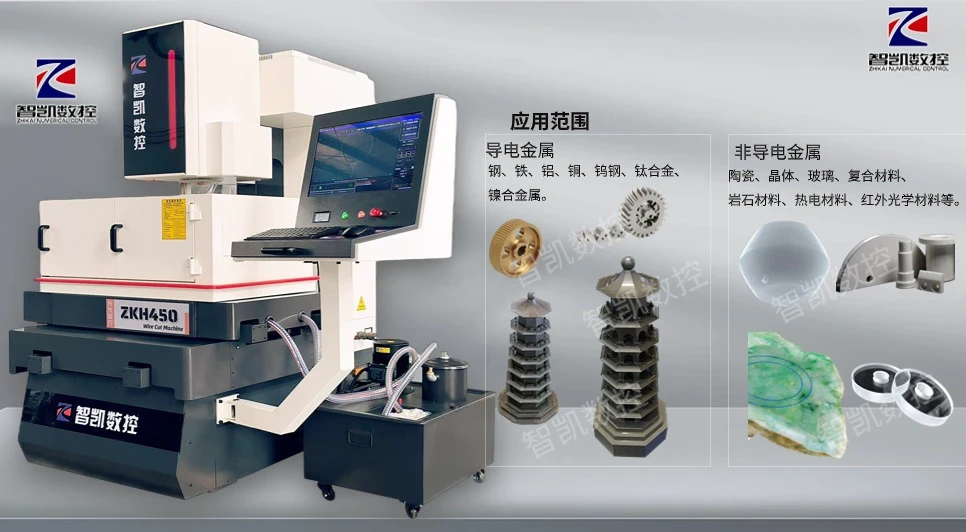

Wire cutting is a mechanical processing process that uses a wire electrode to cut metal or other materials. Although wire cutting is widely used in some industries, it also has some disadvantages, such as poor working environment and complex operation, which may cause some people to be reluctant to engage in wire cutting work.

Whether it is possible to reach 8000 for wire cutting wages depends on many factors, such as work location, work content, work experience, industry demand, etc. In some developed regions or high-paying industries, wire cutting wages can reach 8000 or even higher.

As for whether wire cutting is easy to learn, it also depends on personal learning ability and experience. Wire cutting requires certain mechanical processing knowledge and skills, such as electrode selection, cutting parameter setting, machine tool operation, etc., which requires a certain amount of time and energy to learn and master. For people with mechanical processing experience, learning wire cutting may be relatively easier.

In short, wire cutting is a skill with a certain degree of difficulty, which requires certain knowledge and skills, and the salary level varies from region to region and industry. If you are interested in wire cutting, you can improve your skill level through learning and practice, and get a higher salary under the right opportunity. The above is Suzhou Zhikai's introduction to wire cutting learning and personal development. We welcome more friends around Suzhou to come to our company for exchanges and learning. Contact number: 18013131588 (same number on WeChat)